Hardox® HiAce wear plate beats stainless steel with cost savings and durability in harsh corrosive environments

25.04.2025Corrosive environments in combination with wear, can wreak havoc on heavy equipment. Even materials or aggregates that aren’t usually aggressive can cause corrosion under the right conditions. While stainless steel is well-known for its corrosion resistance, when abrasive and impact forces come into play, Hardox® HiAce outperforms stainless. In this article, Jonas Allebert, senior wear specialist at SSAB, explains why.

One of the applications that Jonas Allebert tested was a garbage truck floor in Hardox® HiAce. Despite the corrosive wear conditions, the extremely low wear rate points to a service life of 20 years

One of the applications that Jonas Allebert tested was a garbage truck floor in Hardox® HiAce. Despite the corrosive wear conditions, the extremely low wear rate points to a service life of 20 years

© SSAB

Jonas Allebert: “I’ve spent many years working with wear-resistant materials. In my experience, Hardox® HiAce represents a significant advancement in wear-resistant steels. It delivers the same excellent hardness, yield strength, toughness and workshop performance as our renowned Hardox® 450 steel – but with one key difference: Hardox® HiAce is specifically designed to tackle corrosive wear. In environments where acids, sulfates, ammonia or salts are present, they create a corrosive wear mechanism that will attack and oxidize the steel surface, dramatically accelerating wear and reducing equipment life.

He adds: “In such conditions, simply opting for a harder steel isn’t enough. That’s why I recommend Hardox® HiAce across industries facing corrosive challenges – from waste collection and pulp and paper to wood handling, recycling, agriculture, and transportation.”

Why stainless steel falls short in corrosive environments

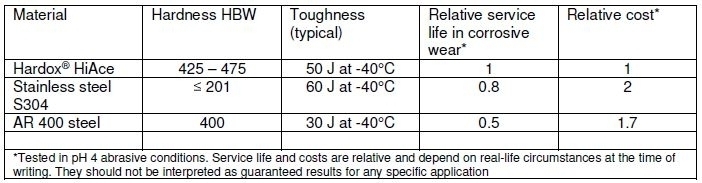

Jonas Allebert: “In tests comparing stainless steel, Hardox® HiAce and commercial AR 400 steel, one clear factor emerged: Hardox® HiAce’s superior hardness. Standard S304 stainless steel, for example, typically measures around 200 HBW. This level of hardness results in a corrosive wear resistance that’s roughly 20 % lower than that of Hardox® HiAce. Moreover, when you factor in the higher material costs of stainless steel, switching to Hardox® HiAce can lead to cost reductions of up to 50 %.

© SSAB

© SSAB

Even if stainless steel manages to avoid corrosion, its relatively low wear and dent resistance often results in premature failure and costly replacements. With a yield strength of around 205 MPa compared to Hardox® HiAce’s robust 1250 MPa, stainless steel is much more susceptible to dents under impact loads. And once dents occur, sliding wear becomes more severe, further cutting short the equipment’s service life.”

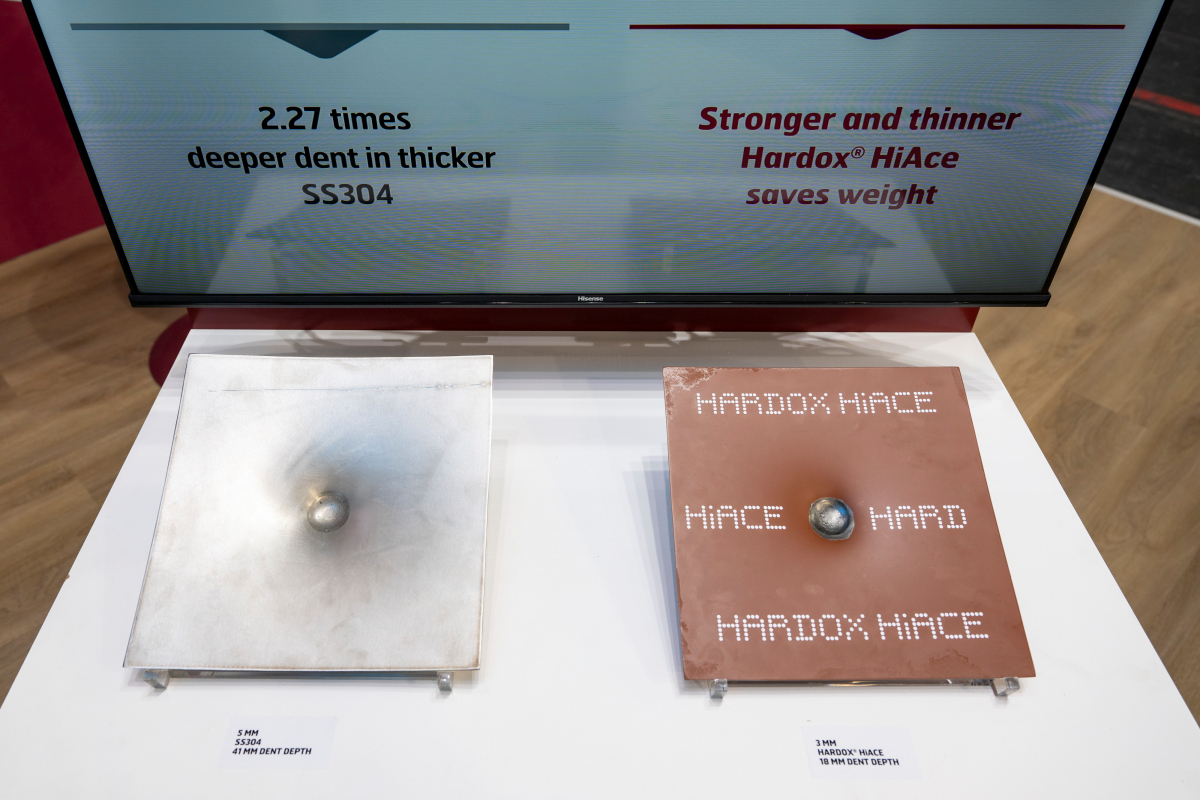

Verified impact dent performance

Jonas Allebert: “I’ve also had the opportunity to oversee impact tests comparing a 3 mm thick Hardox® HiAce plate with a 5 mm thick 304 stainless steel plate. Using a drop hammer rig – with a 250 kg weight falling from 2.82 m – we observed an average dent depth of only 18 mm on the Hardox® HiAce plate. In contrast, the stainless steel plate suffered dents averaging 41 mm, which is nearly 2.3 times deeper. These results clearly demonstrate the practical benefits of Hardox® HiAce in reducing denting and extending service life.

18 mm dent depth in 3 mm Hardox® HiAce, compared to 41 mm dent depth in 5 mm SS304.

18 mm dent depth in 3 mm Hardox® HiAce, compared to 41 mm dent depth in 5 mm SS304.

© SSAB

Real-world success stories

Jonas Allebert: “These impressive test results aren’t just numbers – they translate into tangible benefits for customers. Here are two of their stories.”

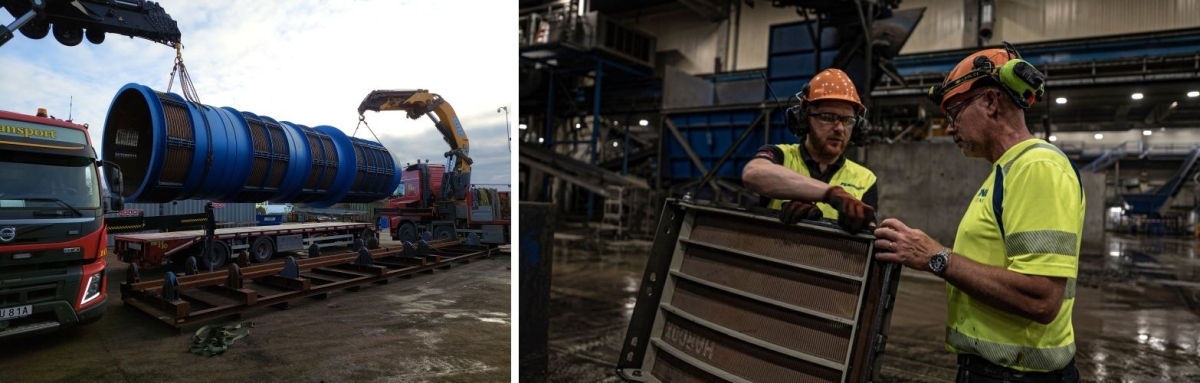

Stena Recycling triples equipment lifespan with Hardox® HiAce

At Stena Recycling, one of Sweden’s leading recycling companies, massive steel drums clean and separate about 1000 metric tons of non-ferrous materials every day. But the wet recycling process created a corrosive wear environment, causing severe damage to the drums. Frequent maintenance and unexpected downtime were becoming costly challenges. Stena Recycling had to find a better solution than stainless steel – and found it in Hardox® HiAce. By making the switch, they tripled the lifespan of their equipment, significantly reducing maintenance costs and operational disruptions.

By making the switch, Stena Recycling tripled the lifespan of their equipment, significantly reducing maintenance costs and operational disruptions

By making the switch, Stena Recycling tripled the lifespan of their equipment, significantly reducing maintenance costs and operational disruptions

© SSAB

The recycling drum contains many grid segments with slits that allow the water to pass through. The previous solution using stainless steel had a shorter lifespan due to wear and impact, since the stainless steel is not as hard and strong as Hardox® HiAce. Stena Recycling runs the grid down to approximately 3 mm before replacing the segments, which translates to about 3 times longer service life than for the stainless segments.

Garbage truck operator looks forward to 20 years of reliable performance

For the Swedish waste management company Allmiljö, durability is everything. That’s why SSAB has been monitoring the wear on one of their garbage trucks built with Hardox® HiAce flooring – an upgrade from stainless S304. After 15 weeks in operation, wear measurements showed minimal material loss – just under 3 % of the original 4.95 mm thickness.

SSAB has been monitoring the wear on one of Allmiljö’s garbage trucks built with Hardox® HiAce flooring

SSAB has been monitoring the wear on one of Allmiljö’s garbage trucks built with Hardox® HiAce flooring

© SSAB

Even more impressively, after 1.5 years, the maximum wear recorded was only 0.27 mm, less than 6 %. Based on these results, the estimated service life of the floor is nearly 20 years. This aligns with SSAB’s wear-corrosion testing, where Hardox® HiAce demonstrated 2.7 times longer service life than the previous stainless steel solution in corrosive wear conditions, but at half the (relative) cost. The extended lifespan also opens the door for future weight-saving design improvements, making the truck even more efficient in the long run.