MBA Polymers install quick clean drawer magnet

01.03.2024MBA Polymers has installed a new quick manual-clean magnet insert into one of their existing Drawer Filter Magnets installed at their Worksop plastics recycling operation in the United Kingdom. The new insert significantly reduces the time needed to clean captured ferrous metal off the high-strength tube magnets, whilst also proving easier and safer for operators.

New quick manual clean Drawer Filter Magnet insert

New quick manual clean Drawer Filter Magnet insert

© Bunting

MBA Polymers UK’s facility focuses on recovering the waste plastics and rubber from “shredder residue” otherwise headed to landfill. These materials are the by-products from the large shredding and metal recovery process of end-of-life automobiles, appliances and other large metal-bearing goods and equipment that are traditionally recycled for their high metal content.

Seven years ago MBA Polymers installed four Bunting Drawer Filter Magnets. A Drawer Filter Magnet has two rows of high-strength rare earth neodymium tube magnets mounted within a sealed outer housing. In operation, shredded plastic (less than 6 mm) falls via gravity into the top of the housing and over the tube magnets. Magnetically-susceptible particles are attracted and held to the tube magnets, allowing metal-free material through to the next stage of the process. Removing this metal is critical for successful recycling, cleansing the plastic and also preventing damage to process equipment later in the plant.

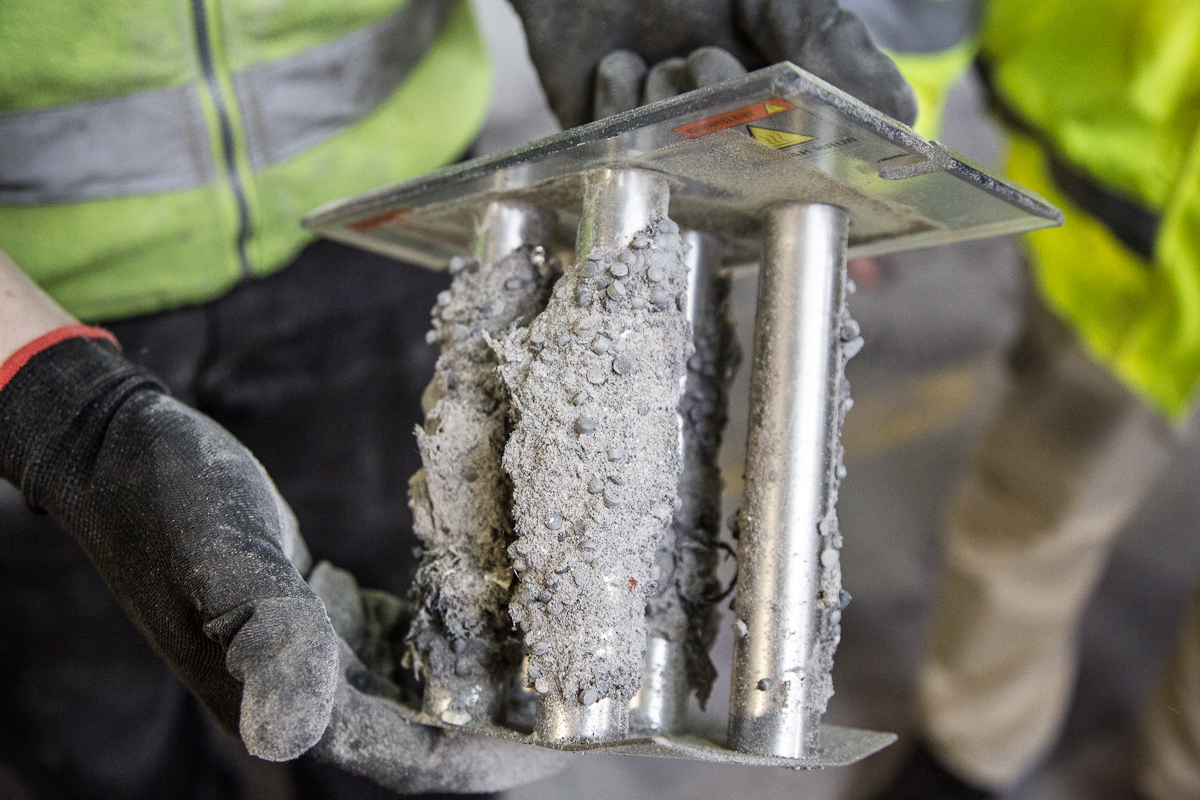

Ferrous metal captured in a standard Drawer Filter Magnet

Ferrous metal captured in a standard Drawer Filter Magnet

© Bunting

Periodically, depending on the level of metal contamination, the tube magnets are removed from the housing and cleaned. Captured metal removed from the surface of the tube magnets is discarded. However, the high strength of the tube magnets makes removal of the metal contamination difficult and time-consuming.

Bunting has developed a new insert to address this problem. The new quick clean magnet insert fits into existing Drawer Filter Magnet housings without any need for modification. With the new design, operators withdraw the complete drawer insert. Once clear, they then pull the tubes magnets through the front Perspex cover. Any metal contamination is drawn to the front of the plate, which is fitted with strong plastic washers that block the metal from moving outside the housing. As the tube magnets are withdrawn entirely, the captured metal is no longer held magnetically and falls under gravity into a separate waste collection area.

Cleaning the new Drawer Filter Magnet insert

Cleaning the new Drawer Filter Magnet insert

© Bunting

With the new insert, cleaning of the tube magnet grid can take as little as 40 seconds, which is significantly shorter than previously. Also, operators do not have to physically remove the entrapped metal from the surface of the tube magnets using either their fingers or another implement, making the new insert safer. Guy Hughes, Extrusion Manager of MBA Polymers, explained the benefits. “With the new magnet system we can ensure that contamination is remove pre-screen allowing an even higher quality product deliverable to customers.”