Resilux set to double bottle-to-bottle recycling capacity

10.05.2021Resilux, one of the leading PET bottle and preform producers, has announced a major new technology investment which will result in them doubling their bottle-to-bottle PET recycling capacity. Using state of the art equipment from Erema, it is Resilux’s latest step in their drive to create a truly circular economy in PET.

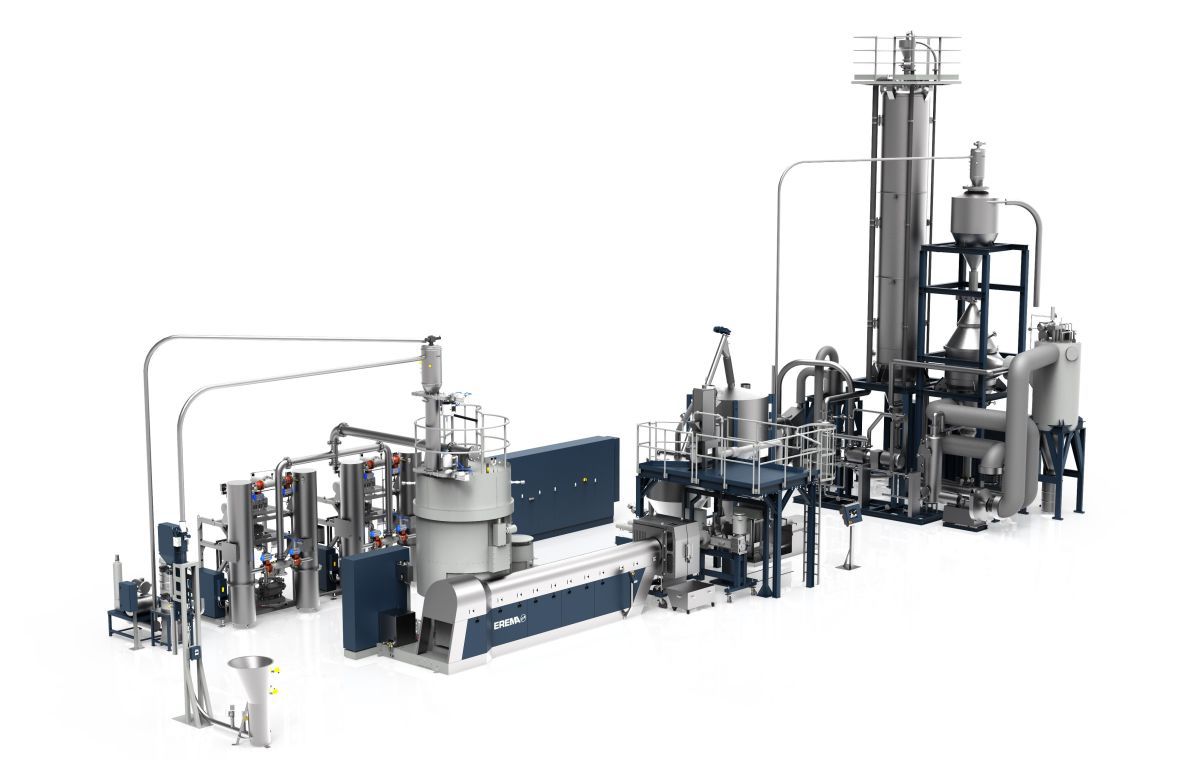

Erema's new VACUNITE® bottle-to-bottle system is installed in Switzerland at Resilux's Bilten site

Erema's new VACUNITE® bottle-to-bottle system is installed in Switzerland at Resilux's Bilten site

© Erema

The new VACUNITE® bottle-to-bottle system enables Resilux to significantly ramp up their production of food grade recycled PET. The new investment has been made in response to increased customer demand and the expectation that production will only increase in the future. Marcel van de Sande, Resilux Group Chief Operating Officer, says: “The new technology puts us in the perfect position to ride the next green wave” by using the “Power of PET”.

The equipment is to be installed at the company’s Bilten location in Switzerland where the Resilux Group Recycling competence centre is based. The investment reinforces Resilux’s commitment to making a complete sustainability loop by creating solutions that are best not only for the products they package, but also for the wellbeing of people and the planet. For them it is another demonstration of being ‘safe for the planet’ – and its ability to be both a versatile and sustainable packaging solution.