Veolia implements AI driven robotic arm to increase recycling at Southwark facility

14.06.2024Veolia has unveiled an innovative robotic arm at its Southwark Integrated Waste Management Facility (IWMF) to optimise operations and make recycling more effective.

© Veolia

© Veolia

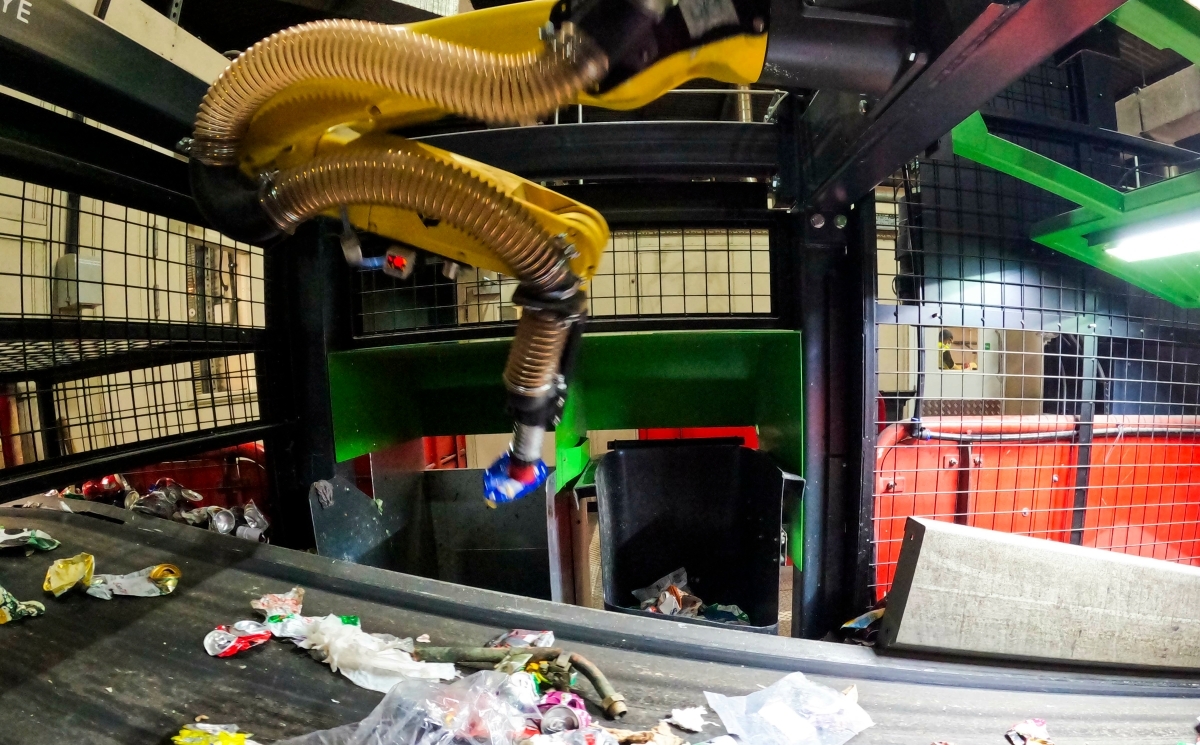

Veolia, one of the UK’s leading resource management companies and Recycleye, an AI robotics business for innovative waste and materials management, have installed a state of the art Artificial Intelligence (AI) technology driven robotic arm that’s as accurate as the human eye. The robot is being used at Veolia Southwark IWMF to pick out paper, card, mixed plastics and beverage cartons, which often contain some aluminium layers, from the aluminium line leaving just pure aluminium items for effective recycling.

As part of its new strategic plan GreenUP, Veolia will use this data to make informed decisions to run the facility at maximum efficiency and monitor seasonal changes in waste composition, accelerating ecological transformation through AI and new innovations.

The robotic solution is made up of a camera, a 6-axis robotic arm, pneumatics system and a compute box. The robot “picks” the item by using compressed air and a silicon gripper, then twists to face the correct sorting bin location and then blows the item off the gripper and into the bin. This advanced innovative technology means that the aluminium picking process can be streamlined and removes contamination from the final recyclate. The robot will pick between 35 and 50 items per minute, supporting frontline staff to increase the quality and quantity of materials recovered at the facility. As the objects pass along the belt, they are also scanned and recorded. This data is uploaded to the cloud and can be presented in the form of user-friendly dashboards.

© Veolia

© Veolia

Aluminium plays an important role in many industries including the green technology sector and is used in large quantities for wind turbines and electric vehicles, two products vital to becoming more sustainable. Improving the capture of aluminium will allow for more effective recycling to support the growing global demand for the metal.

This project is supported by The Alliance for Beverage Cartons and the Environment (ACE) which represents the top manufacturers of food and drink cartons in the UK and Europe.

Commenting on the robotic arm, Tim Duret, Director of Sustainable Technology at Veolia said: “As the UK prepares for the implementation of stronger legislation, such as the Extended Producer Responsibility and Simpler Recycling, Veolia embraces this once in a generation opportunity to integrate new technologies in our UK infrastructure to further optimise our recycling processes. The data presented to us by the robot will give us a better understanding of common materials that are found in the wrong waste streams and how to prevent this, making sure our recycling is as effective as possible. Combining innovation and technology is a major aspect of Veolia’s current operations and future plans, as set in our new GreenUp strategic plan, and we will continue to take a proactive route to change through new improvements and design.”

© Veolia

© Veolia

Commenting about the robot, Victor Dewulf, CEO of Recycleye said: “The ability of robotics to increase efficiency in the sorting of materials for recycling is now well established, and we are proud to collaborate with Veolia to bring our AI-powered sorting robot to Southwark. In particular, this application demonstrates the strength of AI to sort materials such as liquid cartons, which have represented a challenge to existing sorting technology. This is a clear example of robotic sorting supporting greater circularity in packaging, which needs to increase in the context of EPR and Simpler Recycling in the UK.”

ACE UK Chief Executive Richard Hands said: “The Government’s Simpler Recycling reforms will dramatically increase the volume of liquid cartons collected for recycling from curbsides across England. In preparation for these changes, ACE UK is delighted to support the installation of innovative sorting technologies, which will ensure that liquid cartons are separated from other materials so that they can be fully and effectively reprocessed at specialist facilities.”