From a locksmith‘s store to a supplier of complete systems

This saying is quoted by the managing director of Klöckner Siebmaschinen GmbH & Co. KG, Jasmin Klöckner, and thus emphasizes the company motto that only quality pays off in the end, ... and the bottom line is that buying twice is often more expensive.

Founded in 1980 as a locksmith and apparatus engineering company, Jasmin and Alexander Klöckner have been managing the company in the second generation for more than 10 years. The company started with the serial production of screening machines. With growing experience and due to new requirements in the market, Klöckner Siebmaschinen GmbH & Co. KG has changed from a locksmith's shop to a plant manufacturer.

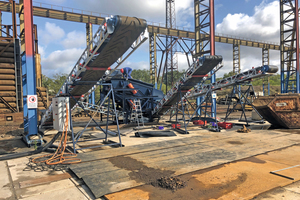

In addition to the main business field of screening plants, the portfolio also includes conveyor technology, bunker construction and special construction. Above all, quality "Made in Germany", expertise and practical experience are important to the Klöckner family. "We are a small but fine team," says Jasmin Klöckner. Klöckner offers a total of four screening machine classes from small to large. These range from occasional use in the area of landscaping to continuous operation for large processors, such as fertilizer manufacturers, soil processors, recyclers and scrap yard operators. Depending on the customer's requirements, these are then adapted to the specific needs – designs with conveyor belt, single or double deck screens, special screen linings, etc.

Apart from the wearing parts, the screening machines have a service life of up to 30 years. To achieve this, all individual components must meet high quality standards. "I like to work with medium-sized companies that have been in the industry for a long time, i.e. have acquired a lot of experience in their respective fields, and have similar demands on quality and workmanship as we do," Alexander Klöckner proudly tells us. The unbalance motors for the screening plants, for example, come from the family-owned company Würges, which has been producing not far from Augsburg since 1950.

Of course, quality also has its price, but Klöckner Siebtechnik also provides assistance in applying for financing, official approval procedures or possible government subsidies.

Jasmin and Alexander Klöckner, the two Managing Directors of Klöckner Siebmaschinen GmbH & Co. KG, met with the recovery team and talked on the spot about the things that are important to them when running a company, interesting experiences and encounters, and successfully completed challenging projects.

recovery: From a locksmith‘s shop to a plant engineering company – this is the development your company has undergone in the last 10 years. What were the reasons for this change and how has the product portfolio of Klöckner Siebmaschinen changed as a result?

Alexander Klöckner: In the past, many more individual machines were sold, and the companies had their own locksmith‘s store so that the plants could be planned and built in-house. Today, there is such a department in very few companies, ergo complete plants including plant planning are requested.

Jasmin Klöckner: Our company employs one staff member, the engineer Hans Jürgen Köster, who is particularly enthusiastic about the design of complete plants. In close coordination with the customer, we then optimize until we have found a solution for the corresponding problem. We also support the companies in applying for and financing the plants.

recovery: How important is contact with the customer?

Alexander Klöckner: We always look at the conditions on site before the project is started. And, what is very important to us, we are honest with our customers and say openly if certain ideas cannot be implemented in this way. Due to our long, practical experience, we can assess very accurately which materials go together with which machines. Openness and reliability are simply the basis of every good customer relationship. Especially now, in times of a pandemic, delivery dates can be postponed because the supply of individual parts becomes more difficult. If such a case occurs, the customer is informed immediately and a binding new date is set.

Jasmin Klöckner: Another advantage of a smaller company is that you can always reach the management. Due to short distances, inquiries can be processed or clarified quickly and without complications.

recovery: After-sales service is also an important criterion for a purchase decision. What experience have you had in this area?

Alexander Klöckner: I can fully agree with that. After-sales service is very important for the customer. For us, a project is not completed until the machine is working to the customer's satisfaction on site. In very few cases do the systems in the more complex application areas run in their optimum range immediately after installation, which is why after-sales service is so important. When the plant is commissioned, everything is once again precisely adjusted and checked by us. Only when the customer is satisfied is the project complete for us.

recovery: You were just talking about the fact that the order books are full. How does a medium-sized family business win its customers – advertising, trade shows or ...?

Jasmin Klöckner: Of course, we also place advertisements and are present at events, but for us, word-of-mouth is what counts most. That‘s why it's so important to us that our projects leave satisfied customers. The industry is not big – people know each other. And a recommendation after a successful project counts more than anything else.

And recently we have had quite a number of interesting projects, such as fertilizer screening at Solvay or the 200 000 t plant for gravel extraction from sea gravel at the Machulez Group, to name just two prominent examples.

recovery: How maintenance-intensive are the machines, after all most of them are in operation almost around the clock?

Alexander Klöckner: There are no completely maintenance-free machines, but we keep our systems so robust and simple that virtually no maintenance is required. Especially in scrap screening, mining, and sand pits, the machines have to run even under tougher conditions. That‘s why they get by without any gimmicks. For example, we do not use electrohydraulic drives for the coarse grates in the bunkers, but kinematic drives. And if a part really needs to be replaced, we make sure that it can be done easily and in the shortest possible time.

recovery: What future plans do you have for your company?

Alexander Klöckner: In any case, plant engineering will be expanded in the future. And the plants will be more modular in design. And of course we will continue to develop our product portfolio, perhaps there will be a compact screen crushing unit.

recovery: Thank you very much for the interesting interview!

https://siebwerk.de

Siebanlagen der Klöckner Siebmaschinen GmbH & Co. KG und ihre Hauptanwendungsbereiche

KS 1015 Siebstrecke 1000 mm x 1770 mm (Breite x Länge) kleinere Anwendungen

KS 2015 Siebstrecke 2000 mm x 1770 mm (Breite x Länge) Mutterboden, Oberboden, Kompost, Humus, Bauschutt, Hüttensand, Metalle wie Aluminium oder Schrott

KS 2340 Siebstrecke 2340 mm x 1770 mm (Breite x Länge) Bahnschotterreinigung

KS 3012 Siebstrecke 1190 mm x Länge 2800 mm (Breite x Länge) Bauschutt, Schrott, Mutterboden

Auftragsbezogene Sonderkonstruktionen basierend auf den entsprechend passenden Baureihen – die jeweiligen Anlagen gibt es in verschiedenen, auf die Kundenbedürfnisse angepasste Ausführungen, z.B. Ein-/Zweideckersiebe, Förder-/Abzugsbänder, etc.