Backers Maschinenbau GmbH

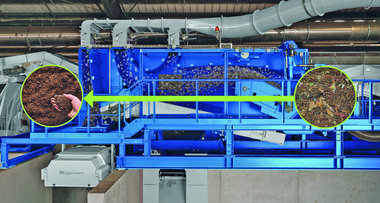

The Backers company is known as a manufacturer of star screens. Since 1989, this technology has been continuously developed for use in mineral and organic materials. Today, even cohesive soil can be loosened and screened with a high throughput, which is a prerequisite for the screening and mixing machine.

Screening

The Backers star screens, such as the 3-mtac or 3-mtbc, are particularly suitable for screening cohesive soil with a high throughput. The coarse particles are separated in front of the machine, while the medium and fine particles are discharged to the side and rear. A 4th fraction is even possible by using a bar grate or grizzly screen. Furthermore, the 3-fraction star screen can be equipped with a magnetic roller and compressed air wind sifter to process construction waste, for example. Coarse material is conveyed directly from the grizzly screen to the side. This is followed by coarse screening, e.g. at 60 mm, followed by further screening, e.g. at 20 mm. Iron is removed from the 20 to 60 mm fraction, while light fractions are blown out using air separation.

A binder container can be fitted in place of the fine sieving star screen deck. This allows the machine to be used as a screening and mixing machine. It is able to stabilise soil and produce HGT and liquid soil.

The screening and mixing machine is transported to the site as a semi-trailer. It is then manoeuvred on site using the machine’s crawler chassis.

Soil stabilisation

The excavated soil is filled into the bunker using an excavator or wheel loader and coarsely screened at around 60 mm. The loosened soil falls onto the lower belt, is weighed and conveyed to the mixing station. The binding agent is conveyed from the binding agent container to the blending station according to the belt weigher. A hammer roller crushes any remaining agglomerates and mixes the soil with the compound. Pre-screening with precise mixing ensures that only as much compound is mixed into the soil as is required for the respective application (usually around 1 to 3 %). Less is more sustainable and can also be applied on site in accordance with the BBodSchV.

Hydraulically bound base courses

For the production of HGT, a coarse screen with 30 mm sieving is used and the mixture is moistened accordingly. An output of up to 300 t/h is possible when producing HGT or stabilised soil. The screening and mixing machine can generate compressed air with a compressor, which is used to convey the binding agent from a separate storage silo to the machine’s binding agent container.

Liquid soil

The mixture of soil and compound is pumped into the truck mixer at the same time as an appropriate amount of water. The liquid soil is produced in batches and documented with a delivery note. It is mixed in the truck mixer for 10 to 90 minutes and then poured.

All mobile star screens can be driven hydraulically, diesel-electrically or electrically.

Booth FM 809/30