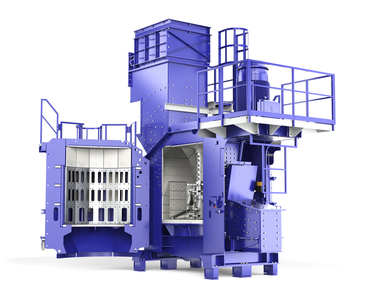

BHS Innovationen presents development

„With the knowledge gained from the development of the smaller SBR 3 and due to the increased demands from customers, the new development of the large screen was a logical step,“ says Florian Schmellenkamp, Head of Business Development at BHS, and continues: „In the asphalt industry, our machine technology is increasingly used for the processing of milled surface material, while in the recycling industry the separation cuts in soil treatment are getting smaller and smaller.“

With the doubling of the engine power and the new development of the vibration system, it is now possible to produce smaller separation cuts and to process material that is more difficult to screen – and this by halving noise emissions. The SBR 4 is designed for wheel loaders with a bucket capacity of approx. 4 m³. With an operating weight of around 5.7 t and dimensions that are tailored to the transport by low-loaders, the appearance is very similar to that of the previous model. However, with a screen section extended to 3000 mm and two excitation motors arranged on the outside of the vibration system, the machine turns into a quiet and powerful linear oscillator.

The BHS machines are known to be simple and robust - attributes that are also fulfilled by the SBR 4. The bar sizer offers the usual protection of the screen deck. Adjusting the machine, in height and inclination, has also become significantly easier with the new linear oscillation system. The motors are maintenance-free and there are no other maintenance-intensive components, such as hydraulic cylinders or conveyor belts. Thanks to the new positioning of the motors, the screen clamping system developed for the SBR 3 could be utilized. The changing of the two screen surfaces with a total surface of 9.6 m² can be carried out in about 1 hour. The entire system manages with 8 clamping screws and is freely accessible with no prior disassembly of baffle plates or similar components required.

Thanks to the quick screen change, the machine can be used flexibly for various screenings and separation cuts. Owing to the automatic ON / OFF function using an ultrasonic proximity sensor, the screening process itself is flexible, as the wheel loader can perform other tasks at any time, e.g. loading customers or feeding other systems.

The BHS Innovationen GmbH is part of a regionally operating, medium-sized group of companies with its headquarters in Dresden. „But not only are the origin and the development from here - the series product is also 100 % Made in Germany!,“ says Schmellenkamp.