BHS-Sonthofen

BHS-Sonthofen, one of the leading suppliers of machines and process solutions in the field of metal-containing composites, will be focusing on metal recovery from metal-containing waste materials such as electric and electronic scrap (WEEE), incinerator bottom ash (IBA) and automotive shredder residue (ASR) at the IFAT 2024. A second focus topic is the efficient and safe recycling of lithium-ion batteries.

BHS-Sonthofen’s mission is “Transforming materials into value”, meaning to extract the full economic value from various materials. The company will be splitting its booth into different topic worlds and showcasing how it is fulfilling this mission in both the recycling of metal-containing residual and waste materials on the one hand and in battery recycling using its in-depth process expertise on the other hand. Our innovative, efficient recycling solutions are the result of our broad technology portfolio, tests in our in-house test center, system engineering and international project management, combined with decades of experience.

Technology leader for metal recovery from metal-containing composites

“We see the pure recovery of valuable metals as one of the key issues in the industry,” says Daniel Zeiler, Head of the Recycling Technology division. “In recent years, BHS-Sonthofen has continuously invested in development to further improve metal recovery from a wide variety of input materials. Depending on the material, we offer an optimized process tailored to our customers’ individual requirements, along with the core machines needed from our own production.” Visitors interested in the metal recovery topic can get an idea of the input material, the respective processing step and the recycling result.

French company Envie, located in the southern city of Toulouse, is the most recent customer to benefit from the implementation of a metal recovery solution. Envie specializes in the recycling of waste of electrical and electronic equipment (WEEE). In 2023, the customer expanded its capacities and markedly enhanced the quality and quantity of its output with the introduction of a new plant, featuring the BHS Pre-shredder and Rotorshredder (type RS).

Complete solutions for efficient battery recycling from a single source

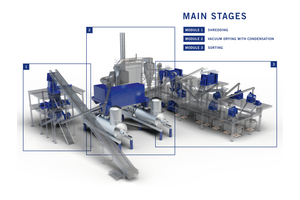

Battery recycling now plays a key role in the development of sustainable energy storage solutions. A few years ago, BHS-Sonthofen developed a new, safe process for the efficient recycling of lithium-ion batteries, which has since proven to be a success on a production scale with several customers. The mechanical drying process occurs within a protective atmosphere and comprises three main stages: shredding, vacuum drying, and sorting. The drying process is supplemented by condensation for electrolyte recovery and gas purification. These three stages have now reached a high level of maturity that they are offered as pre-configured standard modules. The process allows valuable raw materials concentrated in black mass such as lithium, nickel, cobalt, and manganese to be returned to the material cycle at a rate of more than 97 %. In addition, a high proportion of recyclable materials such as aluminum, copper and iron can also be recovered. Visitors can find out more about the process and the solution at its dedicated topic area.

“We are the only provider that covers all the key process steps in mechanical battery recycling on a technological level, uniquely offering the relevant process modules from a single source. Customers benefit from our extensive experience and the combined process expertise in processing and traditional process technology,” Zeiler explains. “For instance, we utilize drying technologies from our Process Technology division typically used in the chemical or pharmaceutical industry.” BASF in Schwarzheide is the most recent customer to benefit from this at its large-scale plant for the recovery of black mass, which is currently under construction. “Together with BASF, we are successfully implementing our third major project in the last two years,” says Zeiler. “This experience ensures process and investment security for the customer.”

Comprehensive portfolio of machine technologies and systems

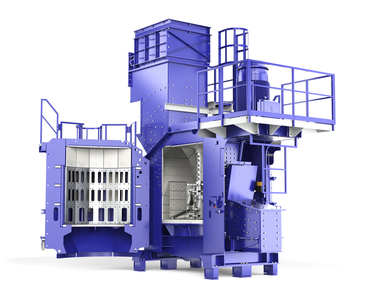

BHS-Sonthofen offers a comprehensive range of machine technology and full-scale plants, including separation and screening technology, for the efficient processing and pre-/post-shredding of valuable waste materials. The latest product development for pre-shredding is the RAPAX, a powerful, universally applicable pre-shredder that combines design and functionality. A versatile and sturdy machine, the RAPAX is particularly suitable for processing various metal fractions and e-scrap, as well as commercial and industrial waste. When it comes to pre-shredding batteries, the Rotary shear type VR is often used as a powerful twin-shaft shredder. The Universal Shredder (NGU) single-shaft shredder is used for pre- and post-shredding a wide variety of materials that can be cut, such as non-ferrous light metals, batteries, data carriers, cables, and refuse-derived fuels. The further development of VR and NGU into fully inertizable and gas-tight machines – developed specifically for the reliable shredding of batteries – is also worth a special mention here.

When it comes to the specialized selective shredding of e-scrap or light metal scrap, BHS offers the low-maintenance and durable Rotorshredder (RS), which selectively shreds, isolates and cleans the input material using impact, shock and shearing forces. Metal components are optimally dissolved and particle sizes are reduced in a targeted manner. The high-performance Rotor impact mill (RPMX) crusher also reliably isolates different materials from pre-crushed, metal-containing material composites and removes cable sheathing and other adhesive substances from metals. Shaping the metals into balls facilitates their separation by type.

BHS rounds off its trade fair exhibit with separation, sorting, and classification technology. Investment in Swiss company RW Recycling World has made it possible to integrate technologies and machines from this sector into BHS processes, offering the user significant added value in processes for recovering unmixed metal fractions.

“As our Group is headquartered in Allgäu, IFAT essentially brings the international industry meeting place to our own doorstep. We look forward to providing visitors from all over the world an insight into the value chain with processes and technologies from BHS-Sonthofen,” concludes Zeiler.

Booth B4-351/450