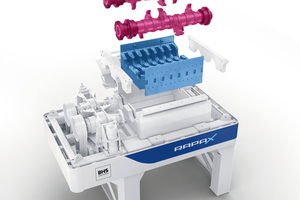

Intelligent pre-shredding with the RAPAX

BHS-Sonthofen’s new RAPAX combines design and functionality in one powerful pre-shredder. Versatile, sturdy and easy to maintain, this machine is perfectly suited for processing various metal fractions, commercial waste, industrial waste and construction waste. The flexible, smart control system also ensures efficient pre-shredding in every running direction.

BHS-Sonthofen has been developing and building shredders for over one hundred years. RAPAX was developed in close collaboration with an industrial designer. The aim was to outfit this innovative technology, which represents a new level in pre-shredding, with an intelligent design. The focus was on functional design elements that make the RAPAX sturdier and easier to maintain, such as the intersecting struts on the funnel, which ensure greater stability. The surface, wall thickness and shape of the funnel are also sturdy and feature precise edges to avoid signs of wear and material build-up. The two planetary gears with belt drive are positioned side by side, as opposed to diagonally opposite, so as to save space.

Equipped for different applications

Efficient shredding is the first important step to a functioning material cycle. BHS offers the RAPAX pre-shredder in a number of different designs and sizes to ensure that it can optimally process a wide range of input materials, ranging from light scrap metal, electrical and electronic waste, industrial and commercial waste, to worn-out drywall and asphalt tiles. It is available as part of either the 15xx or 20xx series in three different sizes, with shaft lengths ranging between 1.2 and 3.2 meters. These allow the RAPAX to effectively shred extremely bulky input material such as construction waste or white goods. Two different tool geometries are available, depending on the design – either the highly serrated BAT shape version for a higher throughput in the case of light waste, or the sturdy JANUS shape for heavy input material. The tearing table is located below the two shafts, which can be used along with the number of tools to determine the particle size. The electrical drive is also available in different power outputs – up to 400 KW can be installed on request. A hydraulic pusher device is optionally available. It ensures continuous material infeed when processing low-density, light or bulky fractions.

In contrast to many other shredders, the center distance of the two shafts on the RAPAX has been deliberately selected to ensure that the tools do not interlock. This ensures an optimal infeed torque with minimal energy consumption at the same time.

Fewer machine downtimes and easy maintenance

“The pre-shredding process sometimes involves a tremendous amount of force. So with that in mind, we placed a great deal of importance on the RAPAX being sturdy and easy to maintain,” says Ingo Schneemann, the responsible mechanical designer in crushing technology at BHS. Rubber buffers have been installed on the drive unit for this purpose, which absorb the impact and protect the gearbox from damage. The design of the tool and the reversing control system prevent material from wrapping around the shafts or adhering to them, which in turn avoids machine downtimes. The machine is also designed to ensure that wear parts such as the shafts and tearing table can be easily removed and replaced. BHS-Sonthofen offers a wide range of services to customers on-site, from installation and commissioning to technical service and maintenance agreements.

An intelligent control system for maximum performance

The shafts can be controlled with total flexibility, meaning they can move synchronously, asynchronously and in reverse. The RAPAX is designed to shred material in every running direction. The control system makes it possible to select the appropriate program consisting of different movement sequences for every input material. “The input materials used by our customers can vary greatly, especially in the area of metal recycling. Whether it’s small electrical equipment or white goods, for example – our various programs ensure optimal shredding,” says Schneemann. The control system could do even more in the future. Plans for the future include using artificial intelligence to make it able to react even more flexibly to the input material. BHS is still collecting the appropriate data for this, but every RAPAX is already equipped to utilize it in principle.