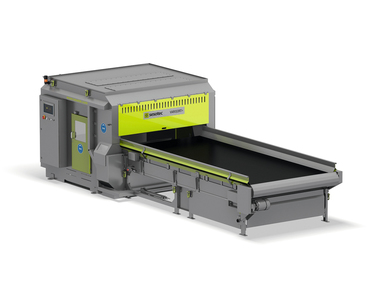

Binder+Co: sorting concept for light packaging

Binder+Co’s sensor-based sorting system is an extraordinary solution for sorting packaging waste such as PET, HDPE, PP, beverage cartons, paper and cardboard. With just one sensor unit, up to six product fractions can be sorted in outstanding quality. The individual fractions are transported with air pressure through a perforated conveyor belt into the respective discharge paths.

Space-saving: The system is fully automatic and compact, which means that only minor investments are required in the substructure and conveyor system.

High product quality: CLARITY multiway ensures excellent product qualities. Light packaging becomes valuable secondary raw material that no longer has to land in landfill sites or be disposed ofin incinerators, but rather can be sent for recycling.

Versatile: CLARITY multiway sorts packaging waste from household and commercial waste, 3D fractions such as bottles, beverage packaging, canisters and plastic containers and 2D fractions such as film, paper and cardboard.

Binder+Co, sorting specialists from Austria, is presenting the solution concept for the growing requirements placed on the treatment of plastic waste live at the IFAT 2018.

Hall B5, Stand 115/214