Experiences from the Stena Nordic Recycling Center with the SPALECK ActiveFEED infeed hopper

Stena‘s website makes the impressive statement: “We currently recycle over 6 million tonnes of material every year – that‘s almost three Eiffel Towers a day.“ With production facilities in Sweden, Norway, Denmark, Finland, Germany, Poland, Italy and the USA, large quantities of complex waste are converted into high-quality, recycled secondary raw materials with the help of constantly evolving recycling processes so that they can be used in production again. In Europe alone, Stena operates 178 recycling plants with more than 3500 employees.

A look back takes us to the 1930s, the founding years of Stena. It all began with the founder Sten Allan Olsson. He had a small office in Gothenburg/Sweden, from which he traded in iron, other scrap metals, rubber and used textiles. Even back then, the focus was on the idea of not wasting resources and returning them to the material cycle. Over 80 years later, many areas such as waste collection, recycling and reuse have been added, as well as many locations and employees. Stena has driven the development of innovative recycling solutions for metal, iron, plastic, paper, hazardous waste, lithium-ion batteries and other complex materials. The company is still family-run, Stena is still privately owned by the Olsson family and the headquarters are still located in Gothenburg/Sweden.

The Stena Nordic Recycling Center in Halmstad/Sweden, went into operation in 2016. The Halmstad site has the advantage of offering good access to road and rail networks as well as a nearby seaport. The Stena Nordic Recycling Center is Stena‘s largest investment to date and covers an area of 433 000 m² with around 400 employees. The center produces high-quality secondary raw materials to replace primary raw materials in production, making the circular economy a reality. When asked what this impressive growth in 8 years is due to, Michael Skoglund, Assisting Plant Manager at Stena Nordic Recycling Center, replies: “A good question, I think pride is an important factor and energy. You have to have determination, so determination in business – and structure.“

The following recyclable materials are processed at the Stena Nordic Recycling Center:

Processing of non-ferrous metals

Processing of shredder light fractions (SLF)

First treatment

Circular electronics

Recycling of precious metals (PMR)

Plastics recycling

The operations at the Stena Nordic Recycling Center reduce the amount of waste that ends up in landfill by 50 % compared to the methods used previously. By investing in new recycling processes, the recycling rate has been increased by 30 % compared to previous processes. Scrap metal from the network of scrap yards is shredded on site at the Stena Nordic Recycling Center and then sent for further classification/sorting.

The latest top performer in non-ferrous processing at Stena is a new infeed hopper – ActiveFEED from SPALECK®, which replaces an unsatisfactory material feed system from a different manufacturer in the sorting line. SPALECK GmbH & Co. KG is also a family business whose roots go back to 1869. Today, the SPALECK Group is one of the leading international manufacturers of conveying and separation technology for recycling and employs around 500 people worldwide.

The new ActiveFEED infeed hopper was developed for, and together with, customers from various recycling areas. After more than a year of testing in the SPALECK TestCenter with various materials, the first prototype was integrated at a customer‘s metal recycling facility. It was an immediate success, with one person less required for manual sorting.

As a material feeding device, it is used as an intelligent pacer for the continuous feeding of machines and primarily for feeding sorting machines of all kinds and raises the quality of subsequent sorting to a new level. This is because the SPALECK ActiveFEED constantly monitors the required preset discharge quantity and automatically adjusts the parameters. The ActiveFEED can therefore react fully automatically to varying material compositions and grain sizes and adapts its discharge performance so that the target quantity is achieved precisely and continuously.

Economic efficiency and customer benefits as a clear basis for decision-making

“We wanted to take sensor sorting to a new level. To do this, we analysed our line. The result of the report was clear: we needed a new type of material feed.

The existing material feed essentially had the following weak points:

Highly fluctuating and discontinuous material discharge reduced the performance of the subsequent sorting process

Recurring blockages in the hopper reduced availability as well as

Damage to the system components

The manufacturer of the XRF sorters also confirmed to us that we could only optimise the output and quality of our sensor sorting if we could achieve a consistent material flow to the sensor sorter.

So we searched the market for a material feed solution and found the SPALECK ActiveFEED. At first we couldn‘t believe it, and I couldn‘t believe it. Because it was so difficult to find exactly the equipment we needed,“ reports Michael Skoglund.

This refers to the performance promise of the ActiveFEED: precise material feed by pressing a button. The user simply defines the desired feed quantity per hour and the ActiveFEED infeed hopper takes care of the rest fully automatically.

A day at the SPALECK TestCenter in Germany provided the clear proof. The experts from Stena sent various materials from their sorting center to SPALECK in advance.

Michael Skoglund: “It was very important for us to carry out these tests. We simply wanted to see what we would buy and what we could expect. And the tests were really successful with our material, which we didn‘t expect. And so we now operate the ActiveFEED here in Halmstadt and are very satisfied with its performance.“

Uncompromising sorting quality and maximum performance with just the push of a button

Lars Dahlstedt, production engineer and expert in sensor sorting at Stena: “Today, we can keep the purity of our materials absolutely constant. There are no longer any differences for our customers.

With the old infeed hopper, we aimed for X tonnes per hour, but unfortunately only half of the required material or far too much material reached the sorting devices. This could vary greatly. But with the ActiveFEED we want X tonnes per hour and we get this throughput rate very precisely, perhaps plus or minus 3 %!“

Michael Skoglund adds: “We were also able to significantly increase the purity of our sorted materials after integrating the ActiveFEED. With the old infeed hopper, the plant operator had to control the discharge manually. It was very, very difficult for him to control the material flow and throughput. It was very time consuming.

In addition, the sensor sorters react very sensitively to variations in the material feed: If there is a surge in the material feed, they are quickly overloaded and reject the wrong metals. This reduces the sorting quality and significantly increases the workload for the manual sorters. If the material feed is too low, on the other hand, the entire line works inefficiently.

That‘s why we used manual sorters in all our fractions in the old bunker. Thanks to the ActiveFEED, we now only have manual sorters in some fractions, e.g. copper.

Our brass is now also purer than before. The ActiveFEED creates an absolutely continuous material feed. This allows the XRFs to recognise the metals much better, create a better solution and separate out the right metals much better.“

In addition, the old infeed hopper experienced serious blockages several times a month. As a result, the system was shut down for several hours each time, as the heavy metal lumps and parts had to be removed by crane.

There are no such blockages with the ActiveFEED, it works absolutely free of blockages and faults. Lars Dahlstedt: “Since the ActiveFEED was installed in summer 2023, we haven‘t had any more blockages.“

Focusing employees on the key tasks and further opportunities

“However with the ActiveFEED, we just press a button with the desired recipe and the ActiveFEED solves this task for us. For example, if we tell it to change the material size and composition from material A to material B, C or D, we just press the corresponding button on the ActiveFEED with the pre-programmed recipe for the desired material. And it knows exactly which parameters it has to use to feed the material in order to continuously supply the throughput we have ordered. It simply works great,“ reports Michael Skoglund and continues with conviction:

“And that is exactly another important advantage of the ActiveFEED. On the one hand, the downstream sensor technology works at a completely new level. On the other hand, the time-consuming manual labour of our employees in manual sorting is reduced. With the ActiveFEED, we control the material supply and thus the business case. We control the reporting and the performance promise for our customers. At the same time, the operators can concentrate on other things such as quality control, maintenance and cleaning of the line. It is also very important to us that the operators now also have time for sufficient regeneration from the demanding manual sorting.“ The ActiveFEED also offers valuable opportunities for new products. Michael Skoglund continues: “We are also currently testing new materials. With the old infeed hopper, we can´t even get the material out of the infeed hopper. But with ActiveFEED we are already getting very good results in the tests. That‘s another big plus for us!“

By the way, replacing the old bunker with the ActiveFEED was very easy. Lars Dahlstedt: “Simply take out the old hopper and put in the new ActiveFEED. SPALECK adapted it perfectly to our existing line. We only achieved our goal of optimised sorting thanks to the new feeder.“

When finally asked about the ActiveFEED, Michael Skoglund reports: “The ActiveFEED really starts our Next Level Sorting show. Without it, this show wouldn‘t exist!“ The manufacturer of the sorting devices also confirmed: “By integrating the ActiveFEED, you are now at the next level of sorting.“

Christian Lake, Sales Director at SPALECK, concluded by expressing his thanks for the long-standing and very successful partnership with Stena: “We are incredibly proud to have worked so closely and intensively with Stena for so many years and are equally grateful for various joint new developments in the field of field-proven 3D screening technology and the recently realised intelligent ActiveFEED feeding system.“

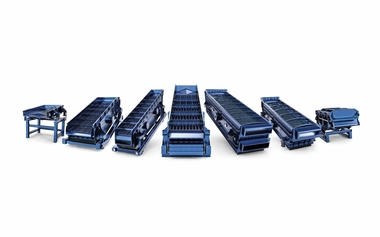

The ActiveFEED at a glance

· Solves the problematic bottleneck of material feeding in front of sorting system

· Continuous material feed even with changing materials and filling volumes in the infeed hopper

· Raises downstream sorting to a new level with maximum material purity thanks to continuous material feeding

· Feeds the optimum amount of material for the sorting line precisely, permanently and fully automatically

· Best performance at the touch of a button: select the desired discharge quantity per hour, ActiveFEED automatically regulates the required material discharge

· Prevents costly underloading or overloading of the sorting devices

· Adapts optimally to changing materials & grain sizes

· Also enables the profitable sorting of very fine and light material

· Standardised sizes from 2 to 50 m³

· Innovative weighing & feeding technology for precise feeding

· Fast amortisation due to increased sorting efficiency

· Significantly reduced need for manual checks by employees (manual sorting)

· Simply retrofit and benefit