Spaleck GmbH & Co. KG

At the centre of this year‘s IFAT the screening machine manufacturer SPALECK is presenting its latest machine and process solutions that make recycling processes more efficient, more environmentally friendly and at the same time more profitable.

The SPALECK ActiveFEED infeed hopper enables first-class performance results of the sorting technology used with the highest purities

The SPALECK ActiveFEED infeed hopper enables first-class performance results of the sorting technology used with the highest purities

© SPALECK

SPALECK ActiveFEED feed hopper:

The highest level of sorting

The decisive factor in sorting is the continuous (uniform) material feed. The SPALECK ActiveFEED feed hopper revolutionises this challenge. Thanks to its self-controlling technology, it ensures that sorting devices are constantly and precisely supplied with the desired amount of material. This enables first-class performance results of the sorting technology used with the highest purities. At IFAT, SPALECK will be presenting the ActiveFEED in new sizes of 25 m³ and more.

Optimised screening processes for optimised recycling

The demands on screening quality have increased considerably in recent years. With its philosophy of “Best Screening. Best Sorting.” SPALECK presents optimised screening processes that have been developed together with and for leading recycling companies. The focus of these screening processes is to provide the best possible screening quality for the downstream recycling process. SPALECK will be presenting these concepts for the recycling processes of metals, plastics, household waste, mixed construction waste, industrial waste, slag and many more.

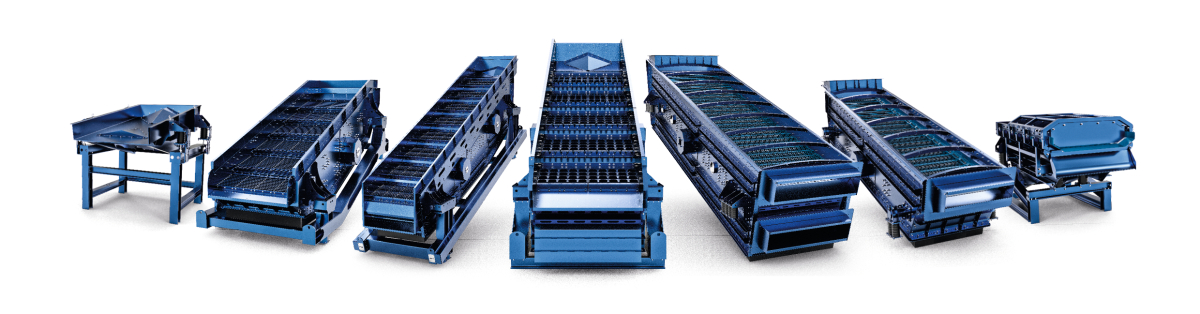

SPALECK provides comprehensive solutions of separation & conveying technology

SPALECK provides comprehensive solutions of separation & conveying technology

© SPALECK

Bespoke screening machines for individual requirements

In addition to screening quality, the flexibility and customisability of screening machines are crucial for the effective processing of different materials. At IFAT, SPALECK will be presenting its expanded ModularDESIGN+ concept. This allows customers to customise their SPALECK screening machine settings to suit their material and material changes as well as their own personal recycling goals. Because SPALECK‘s motto is: My material. My screening machine.

Innovative 3-dimensional screening now

also for flip-flow screens

SPALECK is committed to continuous innovation in order to further improve the efficiency of the screening process. The introduction of 3-dimensional screening for flip-flow screens is another important step in this direction. This technology enables the cleanest screen cuts and prevents the contamination of long parts in the fines. At IFAT, SPALECK will be presenting special screening mats that now also enable the innovative SPALECK 3D screening technology for flip-flow screening machines.

As one of the leading manufacturers of screening machines, SPALECK plays a key role in the recycling process. The company attaches particular importance not only to offering first-class screening technology, but also to taking the entire recycling process into account. At IFAT, material-specific solutions will be presented that take into account not only screening and conveying, but also the process steps of the upstream and downstream recycling machines.

Booth B6, 439/538