Inline recycling with adaptive regrind feed

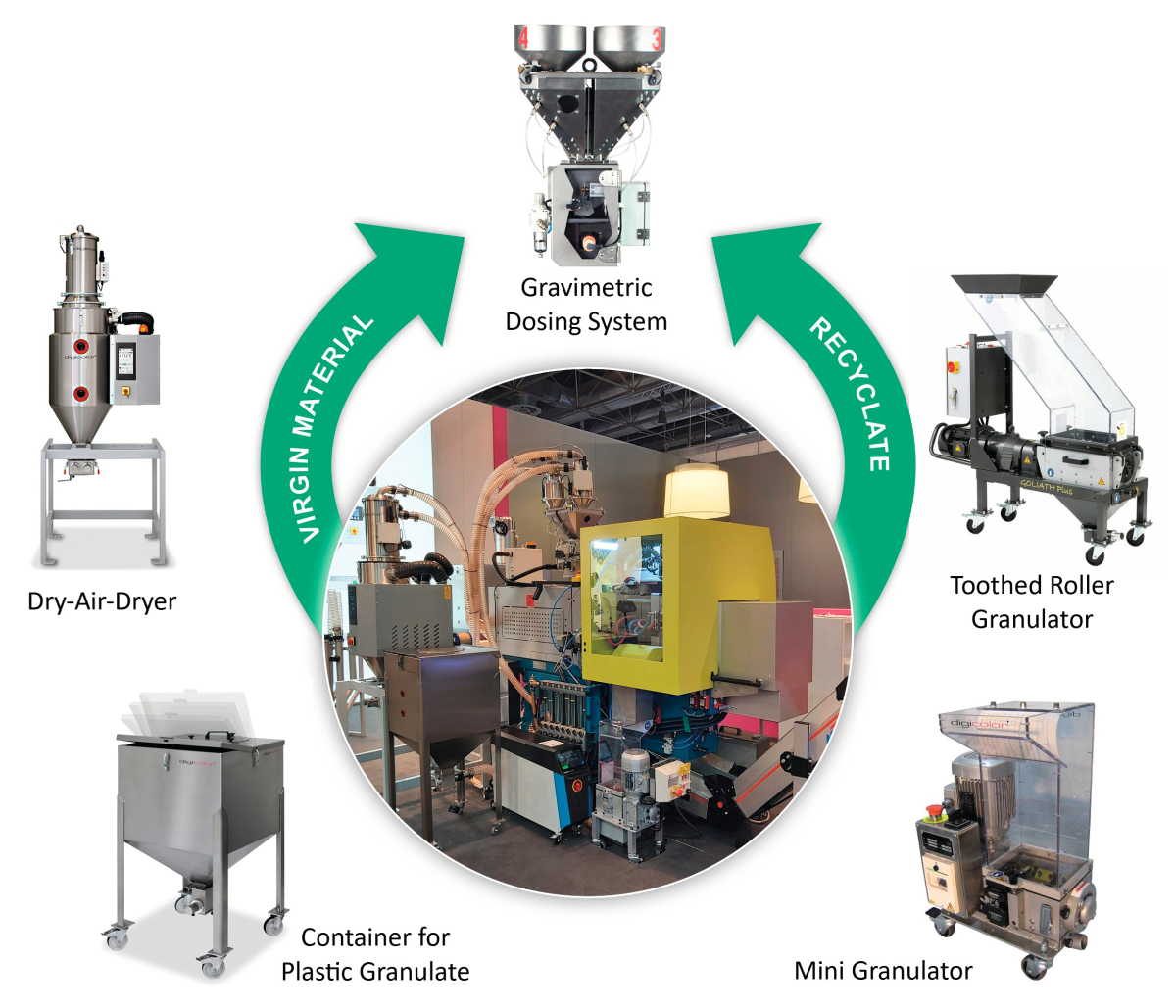

“Recycling turns sprues, rejects and plastic waste into valuable raw materials for the plastics processing of the future.” Digicolor GmbH implements inline recycling projects with this guiding principle in mind. To this end, the specialist for granulate handling systems draws on its comprehensive product range of volumetric and gravimetric dosing systems, application-oriented granulate conveying systems and plastic granulators for the production of recyclate.

Recycling solutions from Digicolor focus on the grinding of rejects and sprues from engineering plastics such as polyamide (PA), polycarbonate (PC), polyoxymethylene (POM) or polybutylene terephthalate (PBT). The recycling of glass fiber-reinforced polymers, such as those used in the automotive industry, also plays a major role today. Directly associated with this is the direct return and dosing of the high-quality regrind obtained from this into the production process of injection molding and extrusion applications.

Recycling cycle diagram

Recycling cycle diagram

© Marco Siekmann

What to look out for inline recycling

The first step is to produce high-quality regrind that is characterized by the following quality properties: Firstly, the recyclate must be available in the most uniform, low-dust grain size possible. Secondly, it must be ensured that recycled material is not thermally damaged by the shredding process. In addition, foreign matter such as metal particles must be avoided. Slow-running Goliath toothed roller mills from Digicolor have proven their worth in meeting these quality requirements.

This is followed by the integration of regrind production with Goliath granulators into the production process. On the one hand, a centralized grinding system with large granulators can be set up at a dedicated location in the processing plant. On the other hand, decentralized solutions are available for many applications, in which rejects and sprues are sorted out and shredded directly next to the processing machines. The regrind is then fed directly back into the machine-related production process via special granulate conveying and dosing systems.

Regrind: green

Regrind: green

© Marco Siekmann

Central granulators are useful, for example, when large quantities of one and the same plastic material are processed on several machines or rejects are collected centrally. From this point, the recycled material is then fed to the processing machines as required via a granulate conveyor system designed to supply several plastics processing machines with virgin material and recycled granulate.

If the quality requirements for maintaining exact mixing ratios of virgin material and regrind are not so high, a mixing diverter that can be easily integrated into the granulate conveying system is recommended. For this purpose, this material diverter is installed close to the feed area of the processing machine, e.g. on or directly in front of the granulate conveyor. This solution is inexpensive and sufficiently accurate for many applications to adjust the granulate flows of virgin material and recycled material in defined proportions of, for example, 60 % virgin material and 40 % regrind.

The use of a volumetric or gravimetric single-component dosing device, which is installed directly on the feed area of the plasticizing screw and below the virgin material hopper, is considerably more precise. The equipment of such a dosing unit includes a special regrind dosing screw, which ensures optimum dosing of the recyclate into the material column of the virgin material. The user sets the dosing process with defined dosing parameters via a convenient touch panel control. The main parameters are the shot weight of the plastic article and the percentage of regrind added. In addition, already known or optimized dosing recipes can be saved and called up again. If several such dosing devices are used on various machines, a central conveyor system for supplying regrind to the devices and processing machines can also be considered.

More frequently, a dosing device is integrated into the machine-related recycling circuit. In this case, the toothed roller granulator is installed directly next to the machine or below the sprue ejector or sprue picker. In this installation variant, the suction device of the mill is connected to the local granulate conveying system or to a single conveying device with a granulate conveying line, which in turn is connected to the dosing hopper of the regrind dosing device. This conveyor system is used to transport freshly produced regrind directly to the dosing device and thus feed it into the production process. This process is called inline recycling. If the amount of regrind available fluctuates greatly, such a recycling system can be supplemented with an “adaptive regrind feed”. This means that the mixing ratio of virgin material and recyclate is balanced depending on the available regrind and within the permissible production tolerances.

If required, this type of inline recycling system can be supplemented with additional peripheral devices, such as additional dosing units for 2-component or 3-component applications. Granulate dryers for pre-drying the virgin granulate can also play a role here.

Precise inline recycling

with documentable mixing ratios

For inline recycling applications where it is important to maintain extremely precise mixing ratios of regrind and virgin material or to document the weight proportions of the mixtures of more than one component, gravimetric batch feeders should be used.

Depending on the application, these gravimetric dosing systems can be installed either on the processing machine or next to the machine. Gravimetric batch feeders work using the gain-in-weight method. In this dosing process, each individual component is first weighed before being mixed with other components and further processing of the regrind/new material mixture takes place. In this way, it is possible to accurately record the weight and document each batch. To save conveying distances and prevent segregation, gravimetric batch feeders are installed directly on the feed zone of the processing machines where possible, where they work reliably despite vibrations. Even with this type of installation, the devices can be conveniently operated and monitored using manual controls. Once the dosing system has been set up, the dosing process runs completely independently of the processing machine in automatic mode.

Recycling solutions with gravimetric batch dosing devices can also be set up in a central material supply topology or as a machine-related system. The recycling cycle diagram on p. 31 shows a machine-related recycling application in which the granulator, sprue ejector on the injection molding machine, granulate conveyor system, pellet container and pellet dryer for virgin material are arranged around the processing machine. The gravimetric batch dosing unit for mixing virgin material, recycled material and masterbatch is mounted directly on the screw feeder. In the application shown, a Mini-Goliath toothed roller mill is used, which can reliably process even the smallest sprues into low-dust, high-quality regrind.

With such a high-quality recycling system, even the manufacture of technical plastic products using the recyclates is possible without any loss of quality.

Digicolor will be exhibiting the recycling applications described at this year‘s Fakuma in Friedrichshafen from October 15 to 19 in Hall B1, Stand B1-1210.

Author: MBA, Dipl.-Ing. (FH) Marco Siekmann, Digicolor Gesellschaft für Kunststoffmaschinentechnik mbH/Herford