JÖST: recovery of non-ferrous metals in the processing of shredded cars

Plant structure with low space requirement

It is the efficient plant structure that leads to a very high processing rate of recyclable fine metal. The recycling process starts with the concentration of long copper cables by using the JOEST long-piece separator. Subsequently, the 0 – 12 mm fraction is screened at approx. 4 mm in the JOEST Flip-Flow Screen TOPCILLA. Both the fraction of 0 – 4 mm and the fraction of 4 – 12 mm reach one of the JOEST K-Sifters. Due to its design, the sifter - seen from the side - forms the shape of a “K”, that is the reason it is called K-Shifter. This K-Sifter is installed above the aspiration hood of the separation table for the pre-separation of very light products in the feed material. This enables a sharper separation and higher throughput, increases the flowability of the bulk material and the efficiency of the sinking process. The K-Sifter, a combination of sifter and separation table, has a compact design. Both components use the same process air, what reduces the exhaust air volume dramatically. The separation result of the K-Shifter corresponds to the values achieved in the individual plants. The design of the air duct makes a flexible reaction – depending on the material, which needs to be separated – possible. Due to the design with relatively small dimensions, this module combination fits perfectly into plants with reduced space availability. The K-Sifter can be supplied in the sizes of 450 mm, 900 mm and 1200 mm width and is compatible with the integrated separation table.

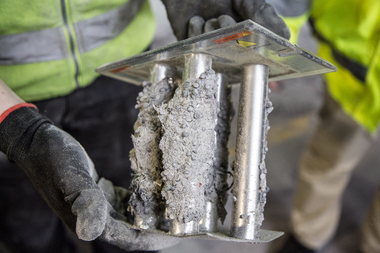

An important feature of the material handling are the vibrating trough feeders of JOEST, which distributes the product over the entire width of the sifter. Rubber curtains prevent additional air from flowing into the sifter. When reaching the sifter zone, the product mixture is separated into light and heavy material through a cross-flow and counter-flow screening process. The ultra-light material is then suctioned off by an aspiration of nozzle, whereas the heavy material enters the separating table and is again separated according to its density. Afterwards, the remaining organic components and the plastic are separated on the separation table. The heavy fraction, consisting of minerals and metal, is led from the separation table into the separator RecoverMax from BPS. The process for which global patents are pending separates the mineral components from the heavy fraction. This system, developed and tested for several years, along with the JOEST processing technologies enables the high quality standard in ASR recycling.

Already at the start-up of the first RecoverMax plant in Ohio, the President of the Mill Iron & Metal, Grant Milliron Senior, said in an interview with Recycling Today: „We are very satisfied with regard to metal recovery. The end product has been meeting my expectations exactly since the start-up.”

Diligence in the further recycling process

In the following recycling process, a drum magnet is used to separate any residual magnetic components from the metal fraction. In another screening machine, the remaining fraction is then classified into three sizes. Next, the material flows of all sizes are fed to the three-socket separating table from JOEST, where the remaining light particles are separated. In the three chambers, the different material sizes are processed parallel to each other, while two unbalance motors provide for the required vibration of the chambers. The air speed and each air flushing valve can be configured separately and individually.

Best rates in recycling, energy consumption and wear

With the plant from JOEST and BPS, metal purities of more than 98 % are possible. In the case of the fraction > 3 mm, heavy metals, such as copper, can be separated from light metals, such as aluminum. Thanks to an additional optical sorter. Due to the development of the RecoverMax, the entire system has very low energy requirements compared to systems based on other comminution technologies, such as hammer mills. Thus, the operating and investment costs are significantly lower.

There are many reasons for success

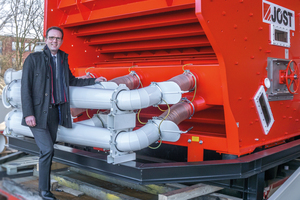

Dr. Marcus Wirtz, the CEO of JOEST, looks further ahead when describing the JOEST/BPS partnership for their success in the market: „Our machines are characterized, among others, by their relatively short design, thus they adapt themselves perfectly to confined space conditions. Moreover, the inner walls, as it is the case with the RecoverMax Separator, are perfectly protected against aggressive impairments. Less wear with high energy efficiency and best recycling rates, this is the result of the partnership for the car recycling between JOEST and BPS.”

At the IFAT the plant will be presented to interested professional visitors who will also be provided with informational material.

//www.joest.com" target="_blank" >www.joest.com:www.joest.com

Hall B5, Stand 429