Optimizing cooling and air flow with Cleanfix Reversible Fans

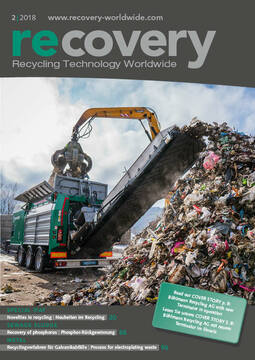

Extreme conditions like these in the recycling industry create big challenges for radiators and cooling systems. The particulate materials clog cooler screens and cooling-fins. The cooling fan act like a vacuum cleaner.

Cleanfix Reversible Fans are the solution. The blades of a Cleanfix fan rotate on their own axis to change pitch and to reverse – through the cross position. An ingeniously simple idea which guarantees that the blade position and with that the airflow will always be aligned and in the most effective and efficient position to produce maximum airflow in both cooling and cleaning modes. Rotating the blades instead through the zero position or changing the rotational direction of a spinning fan, would result in the same effect like eating a soup with the back of a spoon. The cooler screen and coolers are automatically cleaned while the machine is working, at any fan speed and any load condition. The need for manual cleaning is minimized or completely eliminated. Whether in a wheel loader or in a material handler, the productivity increases with a Cleanfix Reversible Fan installation.

Germany-based Korn Recycling has used Cleanfix Reversible Fans for years in continuous duty applications. For CEO Alexander Korn the investment has been more than worthwhile. „By using Cleanfix fans, we saved at least two hours per day, per machine.“

“Our fans are smart,” explains Benjamin Hägele. “Not only do they reverse the airflow to powerfully clean out radiators, but their blades adjust automatically to the engine’s load state so that cooling and air flow are optimized to save fuel – which in turn saves money.”

//www.cleanfix.org" target="_blank" >www.cleanfix.org:www.cleanfix.org