Radiator cleaning with no downtimes

Family-owned Korn Recycling GmbH has its headquarters in Albstadt, to the south of Stuttgart, not far from Hohenzollern Castle. Here, under the family‘s second generation, waste originating from industry, trade and commerce, and also bulky municipal waste, is collected and recycled. Korn Recycling is the successor to a fuel-trading and haulage company founded by the grandfather of the family. The company celebrated its 40th anniversary in 2018.

A glance at the waste that was collected in containers and skips in those days resulted in the idea of founding an independent recycling organisation. The waste delivered in pure-fractions is used to produce secondary resources. Mixed waste is sorted, and pollutants removed, in the ultra-modern waste-sorting facility. High-calorie refuse-derived fuels (RDF) are produced from fractions which cannot be materials-route recycled and are used to replace fossil fuels in the power-generation and cement industries.

A great deal of innovative capability – and even more courage – was needed to get this far. In the late 1990s, Korn GmbH was already operating as a certified specialist disposal organisation with sixteen employees. Initial sorting operations were performed manually, in the form of floor-level sorting, using materials handling machines. The demands made on the recycling industry were growing continuously, and CEO Alexander Korn gave consideration to automated sorting of the incoming commercial and construction site waste.

Production of refuse-derived fuels began in 2002. The year 2005 saw, with the implementation of the Technical Guidelines for the Disposal of Municipal Solid Waste (TASI), the commissioning of the first sorting machine. Construction of one of the most modern waste-sorting and RDF preparation facilities followed in 2008.

Following a dramatic fire in 2009, in which the entire sorting facility went up in flames, a new sorting and refuse-derived fuel preparation plant could already be commissioned in late 2010. This plant features six large shredders, zigzag classifiers, microclassifiers, various screening machines, an induction sorting system, two X-ray and ten near-infrared sorting machines. A great amount of know-how naturally went into the planning and operation of these facilities.

For quality assurance, Korn has its own laboratory to ensure continuous self-monitoring. This makes it possible to determine the parameters of calorific value, chlorine content and moisture content of both incoming flows of waste and the recycled products. Additional analytical equipment, such as an X-ray fluorescence analyser, permit measurement of heavy metal contents.

Korn also sorts, compacts or shreds other types of waste, including paper, cardboard, plastics, scrap and metals, used wood, tyres and mineral waste, for example, marketing the products to corresponding customers. Korn Recycling also undertakes the certified destruction of office files.

Korn Recycling nowadays operates five locations with a total of just on 200 employees. The company, in addition to its recycling operations, also performs other services, such as winter de-icing and road-cleaning, for example. It even has its own logistics division, KORN REKOTRANS, offering freight services both within Germany and internationally.

For Alexander Korn, however, it has always been important to try out new, future-orientated technologies and to integrate them into the production process. His company for this reason participated in the „Material-flow-orientated conceptual solutions for high-grade valorisation of mixed commercial and residential waste“ project, which was commissioned by the German Environment Agency.

„We are also fully engaged in the implementation of the Commercial Waste Regulations,“ Alexander Korn affirms. As long ago as the Hanover Trade Fair of 2013, Winfried Kretschmann, Prime Minister of Baden-Württemberg said, by way of acknowledgement, in a personal conversation: „I am very pleased that you are translating the green idea into action.“

One project in which an innovative solution was sought was the cleaning of vehicle radiators in the buildings where dust-emitting materials are internally transported, i.e. taken to the necessary facilities using materials handling machines. „We were rather desperate, our colleague had to stop the machine twice every hour, step down and clean the radiator using compressed air, otherwise the engine would have overheated,“ Alexander Korn recounts. Then came the tip from a dealer that Cleanfix reversible fans could provide a solution.

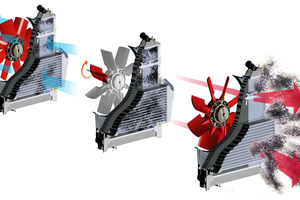

The problem is the dust that clogs up the ventilation and cooling systems under extreme working conditions, such as handling of materials in the recycling sector. Fans which can only change their direction of rotation for blowing out are only an inadequate solution. The flow of air is generated by the wrong profile side of the fan blade. There is insufficient pressure for thorough cleaning, and the ventilation gap, or rather the radiator meshes, gradually become blocked. The results: overheating of the engine, gearbox and hydraulic system. This can cause high costs.

The fan blades of the Cleanfix reversible fans manufactured by Hägele GmbH, on the other hand, can be rotated about their own axis, past the 90° position and almost to the 180° position. The fan operates at full speed during the cleaning process, and the adhering material is detached from the radiator and propelled outwards by the abrupt reversal of the flow of air.

The reason for this outstanding cleaning efficiency? Thanks to the rotation of the blades during the cleaning process, the air is „scooped“ outward by the right profile side of the fan blades, and the high air pressure generated assures highly effective cleaning of the intake filter and the radiator.

High forces are exerted on the fan blades when they are set beyond the 90° position, but it is precisely this positioning which generates the benefit. The great forces acting mean that the right material is also needed for the blades and the mechanism and this is where innovative determination and courage were needed. More than 100 000 Cleanfix fans have now been sold, with global production now running at around 10 000 items annually.

Dr. Petra Strunk, Editor-in-chief at recovery, spoke to Alexander Korn, CEO at Korn Recycling GmbH, and Steffen Hägele, from the management of Hägele GmbH, on the development history of the Cleanfix and on the fruitful interchange throughout the long customer relationship with Korn Recycling GmbH.

recovery: Where did the idea of constructing such a fan come from?

Steffen Hägele: The first Cleanfix was developed by my father. He had a background in agricultural machinery and the agricultural trade. Customers approached him because their radiators were clogging up again and again and it was taking a lot of time to clean them. That was when he developed the first adjustable fan – and the Cleanfix was born! The system was patented in 1998.

recovery: Has the Cleanfix evolved since then?

Steffen Hägele: A lot of development work and a good portion of courage were needed by the mechanical engineer. Initially, a lot of things didn‘t work the way they were supposed to. At the start, the fan blades were made of sheet metal and worked loose. At that time, there was a need for customers who would support this development and were also prepared to take a few risks, but who also recognised the potential of this new technology. One such partner was, for example, Korn.

Alexander Korn: We found Hägele thanks to a tip given to us by a dealer. We were already a customer when the development was still relatively new. The system did, indeed, have some teething troubles, but Hägele dealt with this very openly and took care of everything immediately. That engendered confidence in them.

Steffen Hägele: Nowadays we mainly use glass-fibre-reinforced plastics for the fan blades, for example, the exact composition of the blades also depends on the application – they can also be individually changed using a repair kit.

As an option, modern Cleanfix fans can also be equipped with a cooling-output adjustment system. Adjustment of the angle of the blades (either thermomechanically or electronically) means that only sufficient air as is necessary is drawn in. This frees up, or saves, reserves of power, depending on the application and the necessary force, significantly boosting the vehicles‘ overall efficiency.

recovery: Mr Korn, what made you look for an alternative to conventional fans in the radiators of the materials handling machines?

Alexander Korn: The conventional system means that someone has to blow down the radiator manually using a high-pressure cleaner, the engine has to be switched off for this, and that costs time and fuel. Clogging of the radiator can still occur, even with Cleanfix, of course, but it happens, in our experience, ten times less frequently. An important factor in cleaning is the initial pulse, which is generated in the Cleanfix during operation – when the conventional fan stops and then restarts in the opposite direction not everything will be cleared and the radiator will become blocked.

recovery: How complicated is operation of the Cleanfix?

Steffen Hägele: Cleaning takes place totally automatically. A cycle can be set on a timer and cleaning will then take place for 30 seconds at regular intervals. The radiator is then free of clogging again and the vehicle‘s cooling system continues to operate normally. It is possible, of course, to initiate cleaning manually if necessary.

recovery: Does the Cleanfix have to be retrofitted, or can it be ordered as standard with the materials handling machine?

Steffen Hägele: It depends. Some OEMs offer it as an option, but retrofitting is necessary in most cases. The accredited dealer will then replace the existing fan with a Cleanfix. We do also supply vehicle manufacturers for series fitting, including Fendt, in Marktoberndorf, Case New Holland, CAT and Mercedes-Benz.

recovery: Mr Korn, has it been worthwhile using this new technology?

Alexander Korn: The courage needed to install a new product and also to play a part in supporting development has been rewarded. Properly maintained, these fans run perfectly. We save time and fuel, meaning that the materials handling machines can operate more effectively. We now have six materials handling machines, two CAT wheel-loaders and a Bobcat operating equipped with the Cleanfix system.

recovery: Many thanks for these interesting insights!