PBT develops new technology standard for the

battery and automotive industry

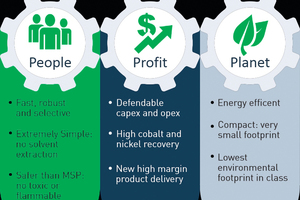

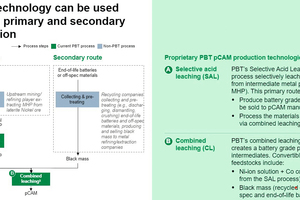

Pure Battery Technologies (PBT) has developed innovative processes to refine nickelmanganese-cobalt (NMC) material required for electric vehicle (EV) batteries. Together with the University of Queensland, PBT has developed two environmentally friendly, low-cost processes for producing nickel-based precursor cathode active material (pCAM) for EV batteries. The combination of Selective Acid Leaching (SAL) and Combined Leaching (CL) produces pCAM more efficiently and cost-effectively, with significantly lower energy consumption and CO2 footprint. The processes are suitable to revolutionize the previous process route for the production of cathode material.

The NMC metal mix needed for batteries occurs naturally in the earth. Conventional processing methods separate each of these three metals (nickel, manganese and cobalt), cleans any impurities and then re-combines them into a suitable mixture. This type of refining is time intensive and requires very large amounts of toxic chemicals, high heat and pressure. All of this requires significant energy, generates a high amount of CO2 and can be expensive.

Cleaning instead of separation makes the big differences

This is where the patented SAL and CL processes come in: In two simple steps, the impurities are dissolved from the existing metal concentrates and the metals are filtered. For these chemical processes, very small quantities of common and completely harmless oxidizing and reducing agents are used; at the end, these are recovered in the processes as harmless salts or flushed out. The appropriate mixture for precursor cathode active material pCAM is then produced from the nickel and cobalt mixture concentrate and can be customized.

The previous complete metal separation and recombination is no longer necessary. Therefore, significantly fewer chemicals, heat and pressure need to be used. Energy, also in the production of chemicals, is saved considerably, reducing CO2 emissions to a minimum. In figures, this means energy savings of up to 70 % and a reduction in CO2 emissions of up to 85 %. The energy saved and the process steps eliminated ultimately reduce the cost and duration of production of the precursor cathode active material pCAM.

Process suitable for all metal raw materials and metal wastes

The processes developed by PBT are suitable both for the refining of raw intermediate materials to produce lithium-ion battery cathode pre-cursor material and for the recycling of black mass, i.e., the cathode waste recovered from old batteries. This also includes the more powerful NMC (nickel, manganese and cobalt) solid-state batteries already planned by some manufacturers for the next generation of vehicles. PBT‘s two processes SAL and CL each fit into existing value chains as a finished component. For this reason, PBT is both planning to build up its own extensive production capacities and seeking partnerships with its customers. „We know we can add value across the whole spectrum of supply chain. PBT has a better and more efficient technology. Customers, whether OEMs, cathode or battery manufacturers, can concentrate on their core tasks,“ says Thomas Fahrner, CEO of Pure Battery Technology Germany AG in Ettlingen.

PBT‘s double strategy: closed loop and upstream

The „closed loop“ in the supply of e-car batteries within the EU is the big goal. The closed loop means that raw materials no longer have to leave the EU for recycling and reprocessing. „Our technology can make a valuable contribution to this, as it is considerably more efficient than the processes known to date. We will revolutionize the production of cathode material as well as recycling with our SAL and CL processes,“ adds Bjorn Zikarsky, CEO, PBT. „Our technology is significantly more efficient than previously known processes. It gives us a unique position on the market, and we want to replace the existing processes. We offer the process to automotive manufacturers, their suppliers, as well as the battery and chemical industries as a readymade component for their production of nickel-based cathode active material,“ says Zikarsky.

Spin-Off of the University of Queensland

The University of Queensland has been researching technologies to reduce the environmental impact of refining metal ores for many years. One focus is on processes for reworking battery-grade metal concentrates into cathode material for batteries in electric vehicles. The opportunity for commercialization, especially for the automotive sector, was quickly recognized. In 2017, Bjorn Zikarsky founded Pure Battery Technologies with Stephen Wilmot and Lachlan Broadfoot. One of the inventors, Dr. William Hawker, joined the team shortly afterwards. The processes were refined more and more, made suitable for series production and eventually fully patented. „PBT is a classic spin-off from the University of Queensland,“ says Zikarsky.

PBT established its first production site in the EU in Hagen/Westphalia. There, the nickel refinery Konigswarter & Ebell Chemische Fabrik (K&E) was taken over in 2020 and PBT‘s own SAL and CL processes were successfully tested in large-scale production and product conformity. At K&E, PBT can immediately process mine material as well as recycled material into pCAM on an industrial scale. Recycling and production capacities are to be expanded to up to 15 000 tons of pCAM material. Translated into end products, this means: pCAM for batteries for up to 150 000 cars the size of the VW ID 3. PBT is planning 150 million € in annual sales in Hagen for 2024/2025. PBT also gained a partner in Germany that should significantly accelerate the company‘s future growth: Cronimet Holding GmbH, a family-owned company based in Karlsruhe, Germany, is a leader in metal recycling and trading. In addition, PBT is a member of the European Battery Alliance (EBA), the EU Commission‘s initiative launched five years ago to build a battery ecosystem, and a partner of Europe‘s largest cleantech investor EIT InnoEnergy.

Growth strategy: First primary material, then recycling

PBT aims to generate 90 % of sales in the upstream segment at the outset. With the increasing sales of electric vehicles, the company expects the recycling share to grow to at least 30 % by 2030. This may even reach 50 % by 2040. „The demand is huge, and the market is growing,“ Zikarsky emphasizes. The demand for EV battery capacity is expected to grow to 2500 GWh by 2030 – up more than tenfold from 234 GWh in 2020. The fact that the number of PBT sites will grow significantly is shown not only by the sales expectation of 1 billion euros worldwide in 2026/2027, but also by the strategy devised by the company: growth should succeed with sites that are close to customers and cooperation partners. The PBT processes can be integrated into existing processes as a module or ready-made component. And they can be used wherever either black mass is produced or where primary materials are processed into cathode material.