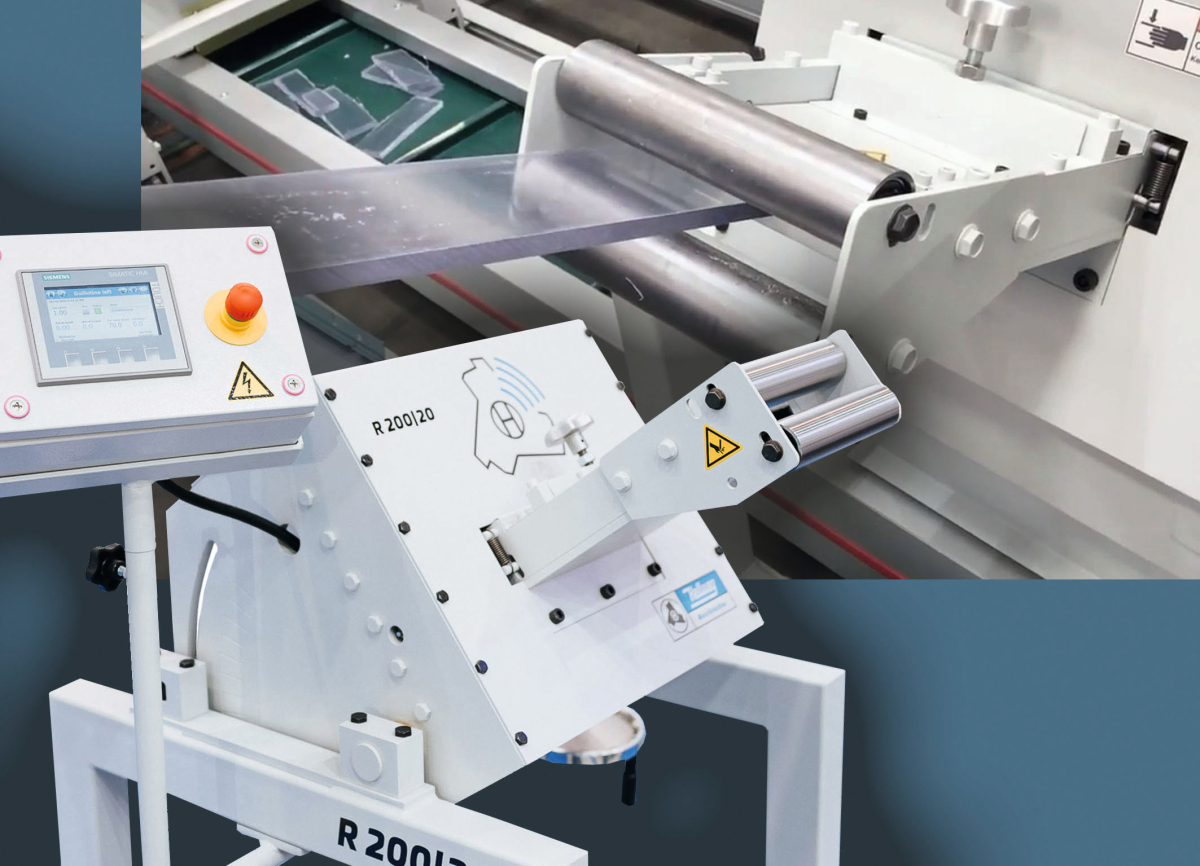

Servomotor-driven edge Trimming System for sheet and film extrusion

Hellweg Maschinenbau’s new, individually controllable R 200/20 Servo edge trimming system brings flexibility to the shredding of extrusion edge strips. Touchscreen control enables processors to adapt this step to production conditions and so optimize it for the specific application.

Jointly developed with BREYER Extrusion, this new machine complements the extensive range of systems, also known as guillotines or chippers, from this global manufacturer of digitally controlled shredding machines for effective, energy-saving plastics recycling.

The touchscreen on Hellweg’s R 200/20 edge trimming system, which is equipped with a servo geared motor, allows cycle times to be freely set. This means that the size and number of individual chips can be optimized for further processing independently of extrusion system output

The touchscreen on Hellweg’s R 200/20 edge trimming system, which is equipped with a servo geared motor, allows cycle times to be freely set. This means that the size and number of individual chips can be optimized for further processing independently of extrusion system output

© Hellweg Maschinenbau

Straight back into the recycling loop

Designed for a working width of 200 mm and cutting thickness of up to 20 mm, the R 200/20 Servo continuously pre-shreds one or two edge strips from film or sheet production. A downstream granulator then processes the resulting chips, which are several centimeters in size, into regrind or flakes in the millimeter range as required. These can then be fed straight back into the recycling loop.

Thanks to a servo geared motor, cutting cycle times can be freely set using the associated touchscreen display. As a result, the cutting frequency of the R 200/20 Servo and thus also the length of the edge strip chips can be selected at a constant cutting speed and so optimized for the output of the respective extrusion system and for input to the downstream granulators. Numerous, short chips relieve the load on lower power granulators, while the longer pieces possible when using powerful granulators relieve the load on the chipper. In both cases, electronically controlled edge trimming cuts down on wear and energy consumption. In addition, the high chopping speed permitted by the servomotor results in a smoother process because the permanently advancing film web only runs against the stationary blade for a very short time. This minimizes any counter-thrust and associated lifting of the entire edge strip.

Maximum reliability in continuous operation

Extrusion requires uninterrupted operation, and this is exactly what the R 200/20 Servo is designed for, just like all of Hellweg’s other granulator systems. Users can be confident that these granulators with their unsurpassed endurance and minimal maintenance requirements will not be the cause of downtime. The durable special guides and the hardened, low-wear blade support and eccentric roller are further factors backing up this confidence.

Energy-saving granulators for every application

As a manufacturer of granulators for any plastics application, Hellweg is expanding its portfolio in step with changing customer requirements. In addition to edge trimming systems, this portfolio ranges from small machine-side granulators for sprues up to high-performance systems for solid parts, film and sheet with a throughput of 5 t/h and above. The digital Smart Control System, featured by all the granulators, captures parameters such as power consumption, motor speed and bearing temperatures, as well as blade, screen and V belt status. By continuously optimizing the ratio of engine load to throughput, it ensures particularly economical operation with minimal operator effort.

For example, the MDSi 340/150 Smart Control machine-side granulator, the most powerful model in the series with drive powers from 1.5 kW to 4 kW, achieves granulation outputs of 10 kg/h to 80 kg/h. The 300 series central granulators, which are as compact as they are powerful, shred thick-walled moldings, sheets, sprue cakes, pipes, and profiles. And the MDSGi 1500/600 wet granulator equipped with a forced feed system, which was premiered at Fakuma 2023, offers an unprecedentedly good ratio of throughput to energy consumption. It produces flakes of consistently optimum quality, as well as a particle size distribution and geometry that are perfect for further processing.