Sorting plant for lightweight packaging officially in operation in Upper Austria

After a construction phase of less than a year and a successful trial run lasting several months, the time has come: TriPlast, one of Europe‘s most modern and Austria‘s largest sorting plants for lightweight packaging, was officially opened by the owners ARA, Bernegger and Der Grüne Punkt together with Climate Protection Minister Leonore Gewessler and Governor Thomas Stelzer. With an investment of more than € 65 million, the circular economy project in Ennshafen has a sorting capacity of 100 000 t/a and creates more than 60 new green jobs.

The owners ARA, Bernegger and Der Grüne Punkt invited guests to the official opening of the new sorting plant for lightweight packaging in the Ennshafen harbour on Friday. “Austria has set itself the goal of doubling the recycling of plastic packaging by 2025. The new sorting plant will make an important contribution to this because it processes materials for subsequent recycling, so that valuable raw materials are not lost. The new plant is therefore an important building block for the Austrian circular economy and also strengthens climate protection,” said Climate Protection Minister Leonore Gewessler.

For Governor Thomas Stelzer, the project embodies a win-win situation: “TriPlast not only benefits the environment, but also the labour and business location of Upper Austria in the long term. There are great market opportunities for Upper Austria as an industrial centre, which strengthens our position as a European innovation pioneer in the field of sustainable industry.”

Secondary raw materials for

Austrian industry

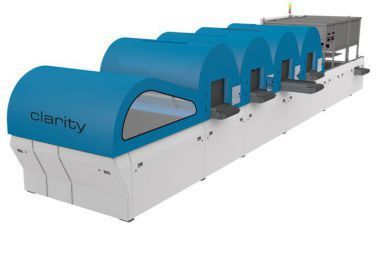

TriPlast has a sorting capacity of 100 000 t of plastic and metal packaging per year. This means that 50 % of all Austrian lightweight packaging can be sorted. Packaging is processed in such a way that it can then be further processed into recyclate and used to manufacture new packaging or other products. More than 20 different raw materials can be turned back into products such as shampoo bottles, canisters, films or components for the automotive and electrical industries. “With our strategic partnership and the cross-border joint venture, we are equipping Austria and the EU for the recycling quotas from 2025. TriPlast can handle an incredible 20 t/h and is three times the size of existing plants in Austria. We want to reduce Austria‘s dependence on raw materials and provide the industry with high-quality raw materials,” emphasised ARA CEO Harald Hauke.

Kurt Bernegger, Managing Director of Bernegger GmbH, emphasised the central location: “The location at Ennshafen in Upper Austria allows trimodal connections by truck, rail and ship. The plant network at the site enables a self-sufficient supply of sustainable energy. As a result, we provide low-emission and climate-friendly secondary raw materials for a successful circular economy and take joint responsibility for our environment and future generations.”

Laurent Auguste, CEO of Der Grüne Punkt, emphasised the cross-border partnership: “The scarcity of resources in Europe requires a strategic reorientation and determined sustainable action. This includes cooperation and investment in the circular economy of the future – such as the pioneering merger of TriPlast.”

TriPlast strengthens Upper Austria

as a location

State-of-the-art technology was installed in the plant: 2.5 km of conveyor belt, 160 km of cable, 2250 t of reinforcing steel, 38 near-infrared devices and 3 screening drums. “With a hall height of 25 m, the new plant will be one of the highest in Europe, ensuring low space consumption and an efficient material flow,” emphasise TriPlast Managing Directors Jürgen Secklehner, Kurt Bernegger and Denis Völler. “TriPlast is also a secure employer in the area of green jobs – we are currently looking for employees ranging from shift supervisors and fitters to electricians.”