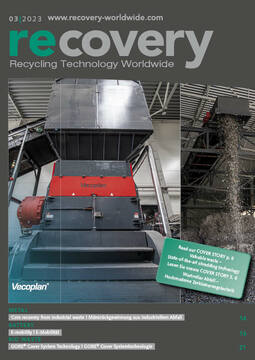

State-of-the-art shredding technology for Sanit-Trans in Poland

Secondary fuels can reduce the costs involved in the energy-intensive production of cement by replacing a large proportion of expensive primary fuels. Sanit-Trans also achieves this by processing various waste fractions into high-quality, refuse-derived fuels (RDF). Vecoplan supplied the shredding technology for a modern processing line during the Covid-19 pandemic – and the outcome? Installation and commissioning functioned very smoothly.

Alternative fuels replace expensive fossil fuels such as coal and oil, so they are a prerequisite for cost-efficient cement production. This is why the Polish company Sanit-Trans Sp. Z o.o. processes industrial waste, bulk waste, light fractions from municipal waste, empty packaging and other typical household items made of plastics, composite material and metal into high-quality RDF.

Sanit-Trans has its headquarters in Międzyrzecze Górne in the Silesian foothills, about 45 kilometres south of Katowice. The company was founded as a sanitary service provider in 1996. The rapidly growing number of customers convinced the company to add waste management to its range of services. Waste management helps to protect the environment, and this became increasingly important for the company – because, in the end, humankind only harms itself by producing too much waste and not disposing of it correctly. The Polish company has continued to specialise in waste management solutions that minimise the negative impact of waste on the environment – always in compliance with European Union directives and based on the best available techniques (BAT).

Shredding at the highest possible standard

A waste sorting plant, a recycling plant for glass shards and one of the most modern processing lines in the country for the production of high-quality alternative fuels have been in Międzyrzecze Górne since 2019/2020. Vecoplan AG was responsible for the supply, installation and commissioning of the company’s integrated shredding technology. The Polish company has relied on the machine manufacturer’s solutions since 2015.

Vecoplan is one of the global market leader in the supply of machinery and plants for storage, shredding, separation and conveyance of primary and secondary raw materials. Based in Bad Marienberg in the Westerwald region of Germany, Vecoplan develops and manufactures machines and plants for processing and handling alternative fuels derived from plastics, paper, domestic waste and commercial waste. The company’s services also encompass consultancy, finding effective solutions and detailed planning. Its integrated project management covers installation, commissioning and comprehensive service. Vecoplan currently has about 500 employees worldwide.

Powerful shredding

“We have implemented a powerful two-stage shredding process that shreds different and demanding materials into one homogeneous output,” explains Ireneusz Suszyna, Area Sales Manager for Poland. The delivered material is collected at the receiving station. An employee picks it up with a front loader and feeds it onto a chain belt that transports the solid materials to a single-shaft pre-shredder of the VEZ 2500 TV series. The developers at Vecoplan have specifically reinforced all the machine areas exposed to exceptionally high forces and loads during the shredding process. An extraneous material detection system also protects the machines from large metal parts. Employees can easily remove extraneous material through the hydraulic bottom flap, speeding up the process by avoiding lengthy downtimes. Vecoplan has equipped the series with a HiTorc drive which works dynamically and has a powerful start-up phase and a high torque. The drive does not require any mechanical elements such as gears, belts, clutches or hydraulic units. The strong shocks and vibrations that occur during complex shredding do not pose any significant challenge for the HiTorc – in contrast to gear-driven units.

Also, less wear and less maintenance is required than with mechanical and hydraulic drives. The drive is fixed to the rotor shaft, so there are no power losses in the drive train, resulting in a much higher operational efficiency.

High-quality output

Now the VEZ 2500 TV continuously feeds the pre-shredded material onto an attached conveyor belt. The bulk material then enters the secondary shredding stage. Here Vecoplan installed a machine of the VEZ 2500 TT series which the company specially developed for RDF processing. Thanks to a high-performance cutting unit, the series is designed for maximum throughput. The patented W-rotor is installed which ensures both maximum cutting performance and an extremely high standard of technical availability. 288 concave cutters are arranged in eight rows and each cutter can be used several times. Users benefit from uniform granularity, long service life and low operating costs. Accessibility for maintenance is also outstanding.

Users have a wide range of benefits

Vecoplan thus supplied a profitable shredding technology with high output quality for the Polish company’s RDF line. This quality is ensured by the powerful pre- and re-shredders and the consistently robust Vecoplan technology that is not susceptible to breakdowns. Vecoplan technology has an extremely high availability level for users and is also economical in consumption. “The VEZ 2500 TV single-shaft pre-shredder and the VEZ 2500 TT re-shredder are perfectly matched in terms of size, throughput and handling,” says Ireneusz Suszyna. “This enables us to give our customer a consistently optimised, safe process which always produces a high-quality and homogeneous RDF output, and is also extremely cost-effective.” The output material is smaller than 30 mm – this was one of the Sanit-Trans requirements reliably met by Vecoplan machine technology.

“When we delivered the post-shredding plant in early 2021, we were right in the middle of the Covid-19 pandemic,” Suszyna recalls. “We certainly didn’t anticipate the impact of Covid-19 when we accepted the order.” The machine manufacturer delivered the shredders on time despite restrictions on entry into Poland. The technicians carried out the installation and commissioning on site without any problems.