Use of air cannons in a circular economy

Europe has a shortage of natural resources but a high demand for metals. Therefore metal recycling has a crucial role to play in securing a supply of metals, tapping into the metal reserves that are tied up in products that are no longer needed. The recycling of metals is a sustainable process that causes no loss of material quality and can be repeated indefinitely. By recycling metals with the deployment of innovative technologies, Europe will be able to meet its demand for metals in a sustainable manner and at the same time minimise demand for virgin metals.

In this context, metal recycling is a fundamental element of a modern circular economy that conserves natural resources, reduces energy requirements and avoids the ultimate loss of valuable materials. Today’s recycling processes vary depending on the consistency and composition of the raw materials and enable the efficient processing of a wide range of recycling materials. The recycling of electronic devices places special demands on the recycling process due to the complex structures and variety of material compositions. The processing of materials arising from unwanted electronic scrap requires special technologies to ensure efficient metal recovery. Metal waste is recycled in dedicated facilities where special processes must be used to handle the complex materials arising from electronic hardware.

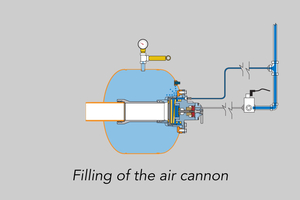

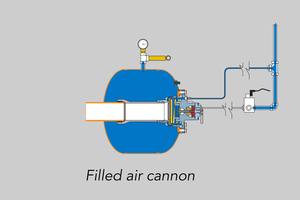

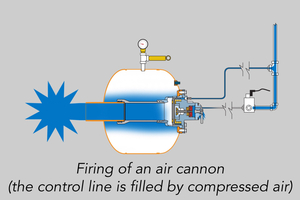

A common problem in the processing of complex recycling materials are hot, toxic combustion gases that are contaminated with suspended solids and clog the exhaust duct after heat treatment. To solve this problem and optimise the process, the HURRICANE® air cannon from Martin Engineering with “Positive Pressure Firing” technology is used. This innovative solution ensures effective removal of combustion deposits from flue gas ducts. Clogging or build-up within a duct due to material deposits is effectively prevented with this technology.

The utilisation of HURRICANE® air cannons in the exhaust duct not only improves process efficiency, but also increases the availability of the entire recycling plant as it significantly increases the available operating uptime. It also improves employee health and safety by minimising the risk of unsafe acts and damage to health as maintenance teams are not required to regularly clean the duct manually. Any need to access inside the exhaust duct by employees can be reduced to a minimum and can be carried out during scheduled plant shutdowns.

The “positive pressure firing” technology also enables longer pneumatic control lines – the positively actuated valve means that the solenoid valve can be positioned up to 60 m away from the HURRICANE air cannon. Several solenoid valves can be protected as a group in a solenoid valve cabinet. The cabinet, and with it the solenoid valves, can therefore be relocated to a “safe” environment away from extreme operational environments. That said, it’s worth noting that environmental conditions have no influence on the performance of solenoid valves.

The air cannon can be easily integrated into existing systems and is a simple to operate. Thanks to its robust design, it is also suitable for use in “heavy duty” environments. The high performance and efficiency of the Martin® Hurricane system means that less compressed air is required, resulting in a reduction in energy consumption and operating costs compared to other models. This contributes to more sustainable performance by making more efficient use of compressed air.

The Martin® Hurricane system is easy to install and requires no special tools. The ease of maintenance provides an efficient solution for air cannon valve maintenance. Thanks to the innovative design, the entire valve assembly can be removed in just one step and replaced within a few minutes. This not only saves time, but also the cost of time-consuming repairs.

Installing the valve on the easily accessible back of the tank is another important advantage of the Martin Engineering philosophy of easy maintenance. It is not necessary to remove the tank from the installation to gain access to the valve, which makes working on the valve even easier and saves time.

There is also no need to lift the heavy tank. This is particularly advantageous in situations where a quick repair is required to minimise downtime. Even in places that are difficult to access, this design and the fact that the tank remains at the installation site reduces the effort required by the service team during maintenance. The same applies to replacing a valve. The simple handling means that maintenance work can be carried out quickly and effectively.

Altogether, the Martin® Hurricane system offers an efficient and user-friendly solution for the maintenance of valve assemblies. Thanks to its innovative design and ease of use, it helps to reduce operating costs and increase productivity.

The Martin® Hurricane system is proven in numerous industries besides metal recycling, including cement, bulk handling, waste processing and many more. It is suitable for use in various environments and applications.

To summarise, the Martin® Hurricane system combines high performance, safety, ease of installation and maintenance, environmental friendliness and versatility. With the Martin® Hurricane operators can count on a reliable and effective air cannon.

Oliver Kämpfer, Sales Manager DACH,Martin Engineering Germany