Westeria AirLift keeps Lübeck‘s compost clean

Biowaste still suffers from contaminants, e.g. plastic, glass or metal, which are thrown into the organic waste bins by citizens all over Germany, as well as in the catchment area of Entsorgungsbetriebe Lübeck (EBL). But the buyers of processed biowaste as compost, preferably in agriculture and landscaping, have to put pure compost into the soil without any interfering substances.

Initial findings from a testing institute commissioned by Entsorgungsbetriebe Lübeck suggest that an area index of 3 – 6 cm2/l can be achieved with the system. In addition to the positive effects of the waste control, which works with trailers in a traffic light system with green – yellow – red, where red as a consequence means not collecting the organic waste bin, the mechanical intervention via the AirLift technology shows the hoped-for, high degree of efficiency for extremely extensive film removal.

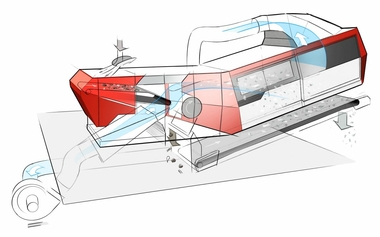

AirLift wind sifter with outstanding

performance spectrum

In Lübeck, the air classifier of the manufacturer from Münsterland, together with the associated high-speed conveyor SpeedCon and the AirWheel module, meets the high demand for reliably separating materials such as plastics with very similar specific densities with a degree of purity of over 99 %. At a speed of up to 4 m/s, the material is flung over a kink in the conveyor belt, while the AirLift located above it extracts the light material. The heavier parts of the organic waste remain on the lowering belt. At the same time, the patented belt steering system prevents the belt from wandering in the guide, so that a longer belt life can be achieved. The precise adjustability of the AirLift with the factors air volume and air speed results in very efficient ballistic flight curves, which are guarantors for the high output of impurities. In Lübeck, this is done with a conveying capacity of 30 t/h and an impurity grain size of up to 20 mm.

Generally speaking, and depending on the volume introduced, the technology used by Westeria can achieve a throughput of up to 320 m³/h, depending on the material. The extracted light materials are transported via a pipe system to the next treatment stage, AirWheel, which ensures the separation of compost fines via drum screens. These are then added to the finished compost as valuable components. The special sealing system prevents the penetration of material components, but allows the fine material and water to pass through unhindered. The separated light materials are used as substitute fuel in a combined heat and power plant.

The system‘s ease of maintenance is underlined by the AirJet cleaning system with compressed air supply as well as the lever mechanism and switching elements, each of which is accessible from the outside and enables inspections during operation. Likewise, an anti-blockade system that automatically raises the AirLift‘s entrance gate to prevent jamming in the event of material accumulation.

The performance of the AirLift system can be tested and proven at any time in the Westeria Technology Centre in Ostbevern with input material provided by the customer. In Lübeck, the AirLift system proves its effectiveness: “We are convinced by the results of the windsifter technology used. If you see the output rate of 250 kg of deformable plastics ˃ 2 mm with your own eyes at a throughput of 250 t of compost, for example, then the new purity of our compost with 0 – 10 cm2/l residual impurities can only be emphasised,” Roman Gradert is satisfied. “This also puts us in a safe position to bring our compost to the market in the future.”