Westeria GmbH

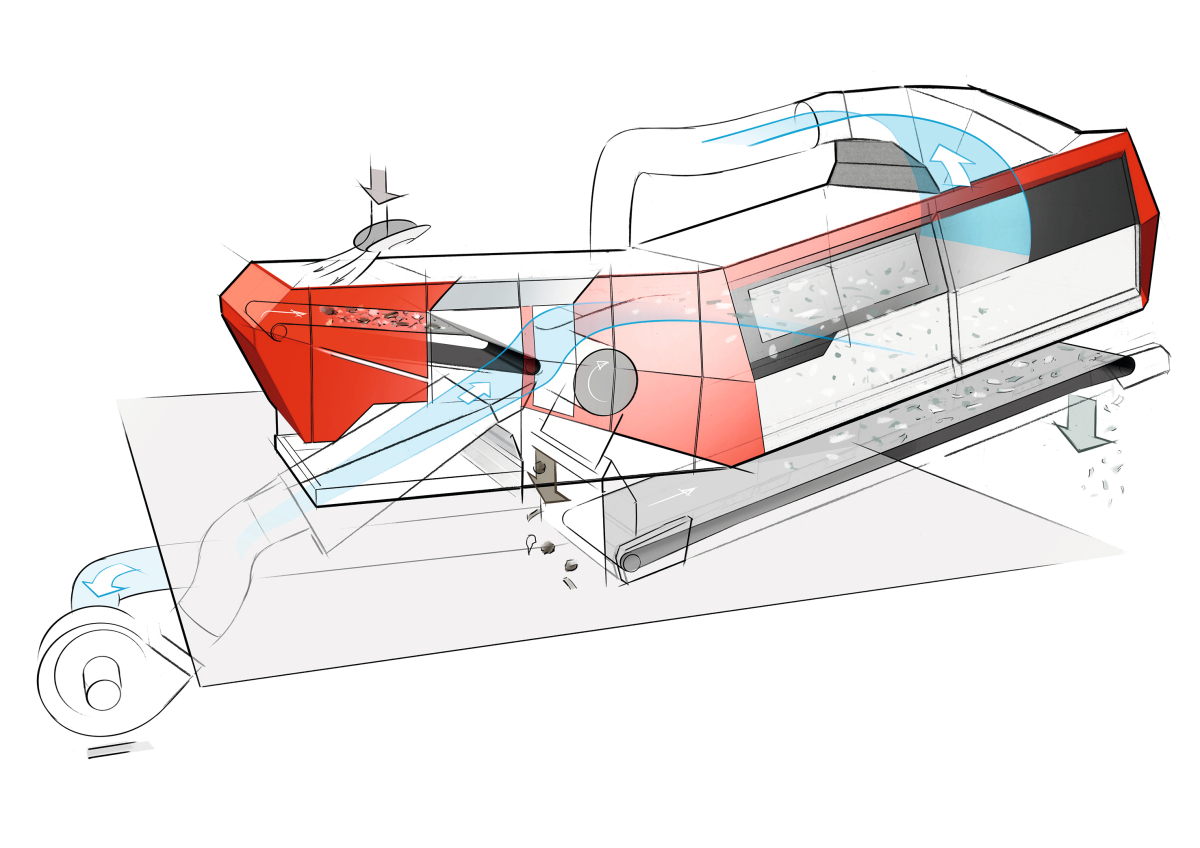

In a world in which recycling is not only an economic challenge, but increasingly also an ecological necessity, Westeria is launching a pioneering solution for material separation on the market with the AirStar® evolution. At this year‘s Innovation Days, the German-based machine manufacturer presented the wind sifter, which has been developed from scratch. In a public web stream, live from the conference hall, the public was also given a detailed look at the machine‘s numerous innovations. With the AirStar® evolution, Westeria is setting new standards in terms of efficiency and flexibility, adapted to the individual needs of users – a milestone that was impressively demonstrated during the Westeria Innovation Days and will also be presented at IFAT in Munich.

An essential part of almost all recycling processes, windsifting enables highly efficient separation of the components contained in waste streams based on their weight and ballistic properties. Westeria air classifiers are used worldwide for applications ranging from household waste to plastics, waste wood, refuse derived fuels, mixed construction waste, waste glass, industrial waste and scrap recycling. The AirStar® is by far the company‘s best-selling model and is based on 40 years of development history.

With the completely newly developed AirStar® evolution air separator, Westeria aims to revolutionize the quality and efficiency of material separation

With the completely newly developed AirStar® evolution air separator, Westeria aims to revolutionize the quality and efficiency of material separation

© Westeria

NotusAir wind guidance system optimizes sorting results

The air guidance system of the air classifier is decisive for the efficiency and precision of the process and therefore the sorting quality. Accordingly, Westeria has invested heavily in the development of this core component of the AirStar® evolution. The result of extensive simulations, flow analyses and tests with different materials is the new NotusAir air system. Its newly designed, adjustable fan enables precise control of the air flow and can therefore reduce energy consumption by over 30 % compared to a conventional, noisier air throttle. To optimize results, the separator drum can be adjusted horizontally, the feed belt vertically and the nozzle angle all fully electrically. The specially designed air routing and a large-area hood over the light material chamber also optimize the entire separation process. This makes it possible for the first time to return a large proportion of the process air to the separation blower, which reduces the amount of air to be extracted by two thirds. This makes the overall system very compact and significantly reduces the investment volume and energy consumption.

Proven advantages inherited from the previous AirStar® technology include the downward angle in the integrated acceleration conveyor, which prevents heavy parts with a larger surface area from being carried into the light material fraction, and the shaftless separating drum as a measure against jamming or winding of material between the drum and housing. The patented, automatic misalignment control in the acceleration belt ensures even more reliable belt misalignment correction thanks to an improved sensor and new algorithm.

At the Westeria Innovation Days, the wind sifter was also presented to the specialist audience with live tests

At the Westeria Innovation Days, the wind sifter was also presented to the specialist audience with live tests

© Westeria

Intuitive operation via simplified controls

For the first time, the AirStar® evolution offers electrical adjustment of all separation parameters from a central and easy-to-understand control unit as standard. On delivery, the optimum settings determined for the customer‘s material in Westeria‘s TechCenter are already preset. Saving individual separation recipes enables the system to be set quickly and precisely for changing materials. The separation process and its adjustment can be observed directly through the large viewing windows on the machine. The new intuitive user interface is so simple that even untrained personnel can operate the machine. The system can also be connected to the operator‘s central system control via the usual interfaces.

Detect faults quickly and rectify them at short notice

The new design of the AirStar® evolution includes a sophisticated maintenance concept. The signal lights, visible from all sides, provide clearly recognizable information about critical machine conditions. In the event of faults, all critical points can be reached easily and in the shortest possible time. Large swing doors allow access to the separation unit from both sides, while additional convenient doors at the rear provide access to the feed conveyor. Thanks to the maintenance flaps in the lightweight material chamber, easy access is also possible here.

Numerous options for every application

Thanks to various extensions, the AirStar® evolution is the stationary cross-flow air separator for all applications. Thanks to the established DiscSpreader material distribution system, narrow, irregular material feeds can be distributed across the entire belt width without the need for additional installation space. To create a third fraction, the new air classifier can be equipped with the DuoDrum system, which uses two separating rollers arranged one behind the other. Alternatively, the AirLift over-belt extraction system, which has also been optimized, can be integrated into the lightweight material chamber to remove ultra-light materials.

Booth B6, 329/428