What can processing technology achieve in the recycling of end-of-life vehicles?

SCHOLZ Recycling GmbH operates a Processing Center for end-of-life vehicles, mixed and collected scrap at its location in Espenhain, near Leipzig. Even before the End-of-life Vehicles Act came into effect in Germany in 2006, a start had been made on the construction of an efficient system for the processing of shredder lights, with the aim of meeting the recycling rates demanded for end-of-life vehicle scrap. The aim during the succeeding years was to decisively reduce manual sorting by means of raising plant throughputs and to increase the yield of NF metals and alloyed steels using new plant-engineering concepts. Another target was that of producing easily marketable refuse-derived fuels (RDFs). In this context, it was necessary to take account of the possible future use of plastics and of changes taking place in automotive engineering. This article examines examples of the innovative plant-engineering concepts derived and the results achieved with them.

The end-of-life vehicles are firstly cleansed of pollutants and drained of fluids at a dismantling company (end-of-life vehicle recycler) – in other words, the battery and tyres are removed, the airbags are deactivated, and all operating fluids are drained off. In addition, the recycler may remove parts for reuse. The remaining body-shells are then generally press-compacted and sold to processing plants.

In order to be able to meet the above-mentioned recycling rates, SCHOLZ Recycling GmbH began, even before the legal provisions came into force, to construct high-throughput processing plants. It was necessary here to bear in mind that the end-of-life vehicle share of the total amount of light steel scrap was only some ≤ 15 % (2005), and later around ≤ 34 % (2009). The predominant quantity of scrap thus consists of so-called mixed and collected scrap (pre-treated large domestic appliances, with the exception of refrigerators; scrap from domestic waste collections; pre-treated small domestic appliances), plus commercial and industrial scrap.

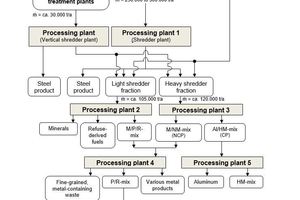

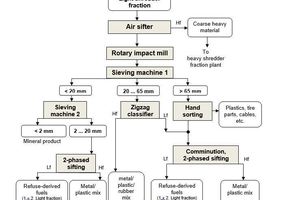

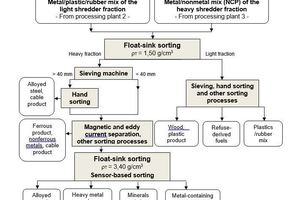

A graduated processing route has been conceived to permit the processing of the many diverse forms of scrap. This necessarily results in a complex plant conception (Figure 1). A number of the relevant plant configurations are examined in more detail below.

Processing Plant 1 – Production of a clean steel product

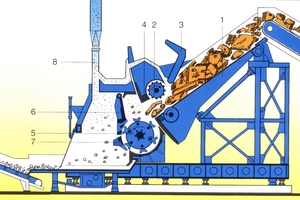

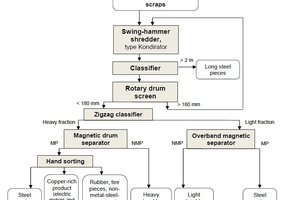

Preparation of light steel scrap firstly requires the greatest possible breakdown of the feed material into its individual components. Swing-hammer shredders with a horizontal or vertical rotor are suitable in principle for this purpose. Thanks to the complex stresses occurring in such a machine (tensile stress, in particular, combined with bending and torsion), a relatively good level of breakdown is achieved. The METSO Lindemann, Düsseldorf „Kondirator“ (Figure 2) installed at Espenhain is an appropriate route if the light steel scrap customarily used in motor-vehicles is to be processed simultaneously with thicker-walled types of steel scrap. Compared to a conventional swing-hammer shredder, this machine features significantly larger screen-deck apertures, at 175 mm, however, which inevitably result in a larger portion of non-broken-down metal/metal and metal/non-metal composites in the comminution product. In order to avoid problems in the downstream equipment and to limit the upper particle size, a special classifier for extremely large particles and a screening drum were installed downstream the Kondirator (Figure 3). The air-flow sorting installed downstream the classifying equipment takes place in a zigzag classifier at an average air velocity of around 15 m/s. The thin walled steel scrap is extracted from the floats thus produced by means of an overbelt magnetic separator, resulting in a relatively low-metal shredder lights fraction. The sinks from the zigzag classifier then pass to a bottom-feed magnetic drum separator, the steel product from which is then manually picked. The shredder heavy fraction then forms the non-magnetic product (see Table 1).

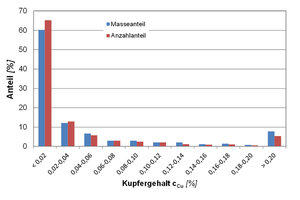

Extensive analysis of the resultant steel scrap indicated that there is only a relatively low Cu content present in the steel. Some 65 % of the particles of steel in the 35 to 60 mm (bar sizer) particle-size class had, for example, a Cu content of < 0.02 % and only 10 % a Cu content of > 0.10 % (Figure 4), while the average Cu content was 0.051 %.

Similar results were also obtained with other particle-size classes. There are thus orientation points for a process for the decisive reduction of the Cu content of the steel scrap. Automatic picking of the steel scrap based solely on X-ray fluorescence analysis achieved only partial successes.

The precondition for long-term operation of the „Kondirator“ system was adherence to the stipulated emissions data in the facility‘s waste air. It proved possible, by injecting water into the comminution chamber, optimising the Venturi scrubber and comprehensive waste-water cleaning by means of dissolved-air flotation, among other provisions, to meet the specified waste-air emissions limits (Table 2).

Processing Plant 2 – Processing technology for shredder lights

The conceptual process takes account of the frequently extremely high and greatly fluctuating mixed and collected scrap content in the material fed to the „Kondirator“. Thanks to this, significantly higher amounts of mineral constituents pass into the shredder lights, compared to „pure“ end-of-life vehicle scrap. On this basis, a plant-engineering concept pursuing the following objectives was developed:

a) Production of a landfill-suitable mineral product

The decisive factor in maximum separation of the mineral constituents is the largest possible „fluidisation“ of the shredder lights, combined with the breakdown of clogging, the detachment of fine-particled adhering matter and the comminution of the coarse-particled mineral components (glass, etc.). Subsequent screen classifying at w ≈ 3 mm results in a screen underflow of > 80% < 1 mm, which is used as landfill construction material. The recovery of an Fe concentrate from the fines for use in blast furnaces using weak-field magnetic separation is also conceivable in principle.

b) Production of a refuse-derived fuels for use in cement plants and alternative-fuelled power-generating plants

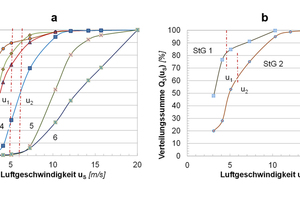

The aim of producing a high-energy, very largely metal-free, fuel is achieved by means of air-flow sorting. Fluff, foams, films, wood and thin plastic items in the floats are extracted in a zigzag classifier at low air velocities (Figure 5a). The most extensive quantitative separation is achieved at relatively low solids burdens (< 0.5 kg/m3) and by means of two-stage classifying. The simultaneous extraction of extremely small metal contents, generally in the form of wire, which could be separated out only after its spheroidization in a turbo-rotor mill, is unavoidable. The resultant substitute fuel (Floats 1 and 2) has a calorific value (Hl) of 18 MJ/kg DM (dry matter) with a Cl content of around 1 %.

c) Most complete possible accumulation of the thick-walled plastic items, steels, all NF metals and their composites in an intermediate product

The relatively low average air velocity in the second zigzag classifier, too, inevitably results in a high metal yield in the resultant sinks (steels, NF metals, metal-containing composites – mixture of metal/plastics/rubber). The 2 to 0 mm particle-size class was analysed at a low solids burden in a laboratory zigzag classifier.

The process flow sheet developed on the basis of the above-mentioned objectives and of extensive analyses and tests is shown in Figure 6, and corresponding results in Table 3.

Processing technology for the shredder heavy fraction

Processing Plant 3 – Production of an aluminium/heavy metals mixture

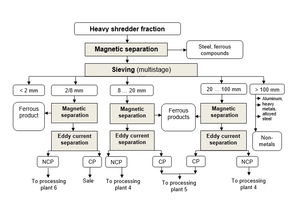

The shredder heavy fraction must firstly be classified (Figure 7) in order to achieve high efficiency in the downstream sorting processes. This is accomplished in multiple stages, a high moisture level having negative effects on the separation intensity of classifying at 2 mm. Tried-and-proven equipment is used for magnetic separation and eddy-current sorting. Practically all the resultant products, with the exception of the < 2 mm screen fraction and the magnetic products, are further processed in downstream facilities.

Processing Plant 4 – Recovery of the remaining metals and preparation of a high-plastics product

Several metal-containing, high-plastics waste flows of greatly differing composition were produced in the course of the previous processing of shredder light and heavy fractions. Further processing of these needed to attain the following aims:

Maximum recovery of the metals content in the form of saleable products

Production of a plastics/rubber mixture suitable for further sorting of plastics

Preparation of a refuse-derived fuel containing as little as possible of the recyclable plastics

Extensive preliminary tests indicated that float/sink sorting creates good preconditions for the attainment of the above-mentioned objectives.

Float/sink sorting performed in a magnetite medium at a density of rT = 1.5 g/cm3 supplies an extremely low-metals float fraction. Metal contents of < 0.5 % occur in sorting of the 5 to 20 mm particle-size class, while slightly higher Cu losses occur in the coarser particle-size classes as a consequence of „catching“ of copper wires. Combustible-constituent content in the sinks is close to 10 %. Density analyses indicated that the combustible constituents contained in the sinks were almost exclusively of a density of > 1.55 g/cm3. The very high separation intensity of the float/sink process was thus confirmed. The magnetite losses which occurred were definitively determined by the foam content in the floats product; losses of < 1 kg/t are associated with the sinks.

Technical implementation of the above-mentioned targets was accomplished in two separate systems, for the 5 to 20 mm and 20 to 100 mm particle-size classes. Figure 11 shows the process flow sheet for the 20 to 100 mm particle-size class. It proved possible to design the equipment for the 5 to 20 mm particle-size class rather more simply.

Processing Plant 5 – Float/sink sorting of the aluminium/heavy metal mixture

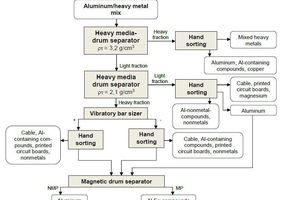

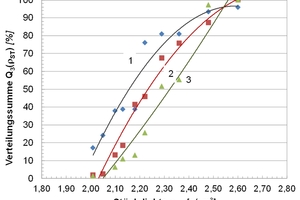

Float/sink sorting and automatic picking on the basis of X-ray transmission analysis are processes available for the sorting of aluminium/heavy metal mixtures. A two-stage float/sink sorting process was selected on the basis of the separation results obtained in commercial-scale studies using the two sorting processes, the desired throughput and potential use for other separation tasks (Figure 8).

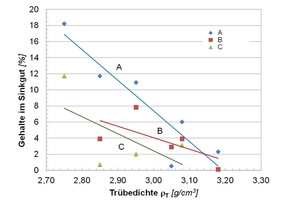

The first stage takes place in an FeSi dense medium with a medium density of around 3.2 g/cm3. If this density is not attained, too much aluminium and aluminium-containing composites will be transferred into the sinks (Figure 9). FeSi losses amount to 4 to 6 kg/t, about 85 % being attributable to adhering fouling, as well as piping and folded sheet metal either not or only partially drained of liquids. The resultant sinks are then cleansed of aluminium and aluminium-containing composites and picked for copper, in order to achieve higher revenue. The product designated as „mixed metal“ consists of the remaining copper, brass, zinc, lead, alloyed steel and heavy-metal-containing composites.

A magnetite suspension with a density of around 2.1 g/cm3 is a suitable medium for the second sorting stage. Magnetite losses are of the same order of magnitude as in the first stage. The resultant sinks (density class 2.1 to 3.2 g/cm3) are classified using a bar sizer, in order to facilitate downstream manual picking. A screen overflow to screen underflow ratio of around 2/3 to 1/3 by mass proved to be highly advantageous in terms of picking efficiency.

The floats (density class up to 2.1 g/cm3) consist predominantly of Al/NF metal composites and non-metals, and also of free „fluidised“ Al malleable and cast alloys featuring corresponding open and closed cavities. The latter are sorted out manually and subjected to magnetic separation together with the „clean“ 2.1 to 3.2 g/cm3 density class. This supplies an Al product with a very low Fe content.

Analyses of the particle density of printed-circuit boards (PCBs) with no, with few and with many electronic components demonstrated that the PCBs have a broad density distribution (Figure 10). They are predominantly in the 2.1 to 3.2 g/cm3 density class, however, with the result that they can also be picked automatically using a colour CCD camera, instead of manual picking.

Processing Plant 6 – Recovery of metals from the fine-particled, low-metal, high-mineral, plastics-containing waste flows

Low-metals waste flows with greatly fluctuating mineral and organic component contents are produced in Processing Plants 3 and 4. The development of a process both suitable for this and, at the same time, cost-efficient, constituted an enormous challenge. This plant was, nonetheless, commissioned in December 2018. The process, developed in the course of many years, was ultimately patented in May 2019.

Processing technology for plastics/rubber mixtures

The plastics/rubber mixtures produced in Processing Plant 4 contain 50 to 70 % plastics, 20 to 30 % rubber and 5 to 10 % wood. The Cl content of the mixture is between 1.5 and 3%, with both plastics (PVC etc.) and types of rubber containing chlorine. The calorific value of the mixture reaches figures of > 28 MJ/kg DM.

Before any activity for the further processing of the plastics/rubber mixtures is started, orientation points for sale of the high-chlorine products inevitably generated must be defined, since the recovery of a high-quality plastic (PP, PE, ABS, PS, etc.) and/or of a low-chlorine refuse-derived fuel (RDF) is necessarily linked to the accumulation of Cl in the remaining matter.

Automatic picking on the basis of X-ray transmission and float/sink sorting at a medium density of rT = approx. 1.20 g/cm3 is a route suitable for the production of a low-chlorine RDF. The resultant product (density class -1.20 g/cm3) could also be used as granulate in blast furnaces. Where the emphasis is on the recovery of high-quality plastics mixtures, only density separation at a medium density of rT = 1.08 g/cm3 could be considered up to now. Automated picking of the economically valuable plastics has not up to now been possible at a rational level of effort and expense, since these plastics are predominantly black when used in automotive applications.

Overall result

It has been shown that the processing plants constructed in Espenhain have made it possible to overfulfill the recycling rates legally stipulated for end-of-life vehicles since 2015 (Table 4).

The extremely good results obtained are explained by the plant-engineering concepts selected, which

permit an extremely high metals yield

transfer the glass content of the end-of-life vehicles entirely to the mineral product and

deliver a saleable refuse-derived fuel

Only around 3 % by mass need to be counted as losses; in other words, the targets of the circular economy are met to a high degree.

Future prospects

Recycling organisations are currently being confronted with ever more new challenges, thanks to increasing electromobility and the rising use of Li-ion batteries in numerous mobile devices and other equipment. The increasing use of carbon-fibre-reinforced plastics (CFRP) in automotive engineering, as well as their use in some cases as metal/CFRP composites, is generating new demands on comminution and sorting equipment, and, above all, on analytical methods. Scholz Recycling GmbH is pleased to face these challenges and has already initiated corresponding research into a number of the tasks requiring solution in the future.