What is behind it?

Red is the company colour of the construction machine builder company Hammel Recyclingtechnik GmbH from Thuringia and the „giant“ stands for a 2-shaft pre-shredder that is produced there. The company HAMMEL Recyclingtechnik GmbH, based in Bad Salzungen in the heart of Germany since 1996, developed the HAMMEL shredder type VB 950 DK – RED GIANT. This machine type, which got its name from an employee suggestion, is the largest machine with a CAT C18 diesel engine with approx. 760 hp in the primary crusher product range.

Developed a few years ago as a wood shredder, the machine primarily shreds large, difficult-to-handle roots and waste wood. Enormous throughputs of approx. 150 – 200 t/h can be achieved in this area. The 2-shaft shredder is used in the material and thermal processing of waste wood, but is also an important primary shredder in the processing of fresh wood.

The meanwhile well-established machine is given new tasks all the time. Application area for example the shredding of general household waste processing, construction waste, large-volume industrial and commercial waste are added. The shredders are installed at first equipment for shredding in incinerators, mechanical-biological waste treatment plants for household waste and also for volume reduction at waste handling sites. About 15 years ago, the third task area, the processing of car bodies and light mixed scrap, is expanded.

At the beginning of the development in the area with the RED GIANT, the company carried out a self-test and successfully shredded some car bodies. This was the hour of birth of what is now an important area of processing old car bodies and the processing of aluminum profiles, blocks and light mixed scrap.

What makes this multifunctional,

slow-running pre-shredder special?

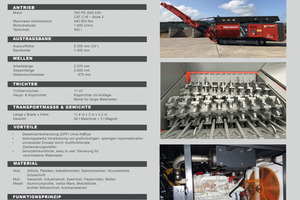

The machine is constantly being further developed and adapted to the requirements of the market. In addition to a modern design in red/gray, the self-propelled mobile chain shredder is characterized by an optimally designed discharge belt with a discharge height of approx. 5000 mm. This means that high mountains of material can be created or the shredded material can be loaded directly into the truck. The laterally installed overbelt magnet is fixed in a holder in such a way that it is always in parallel position when the discharge height of the discharge belt is changed hydraulically. This has the advantage that the magnetic belt is optimally adjusted.

The HAMMEL primary shredder also has the latest generation of hydraulics, which enables a significantly higher nominal torque on the shafts compared to the previous machines. The engine speed was also reduced to 1800 rpm, so that by saving the cooler, an enormous noise reduction could be achieved. Like all HAMMEL machines, this primary shredder also has the proofed „easy-to-use control“ system. This is characterized by its extreme user-friendliness. Parameters such as shaft speed and reversing times, pressure settings and machine parameters can be easily viewed and adjusted. In the simplest way, 3 permanently installed shredding programs and 1 free one can be selected on the colour display, depending on the shredding material. Several language options and error messages are displayed in plain text, making operation and maintenance easy and customer-friendly.

The biggest advantage is the multifunctionality with high throughput rates in almost all bulky, voluminous input materials. Universal shredding shafts are used, which in various designs achieve a coarse, medium or fine end product. Due to the interlocking knife arrangement, the intake behavior of the input materials is optimal for shredding. The machine is an important component, especially in metal processing. Input materials such as light mixed scrap, car bodies, aluminum bales, etc. are broken down and prepared for further processing (screening, separating, secondary shredding).

The machine type VB 950 is also offered as an electric variant with 2 x 250 kW drive power. Rising raw material and diesel costs enable customers to have flexible solutions in the plant area.

In the meantime, the HAMMEL VB 950 – RED GIANT is working worldwide in a wide variety of applications. Whether in Buenos Aires with a daily processing of 1000 t of household waste, on almost all continents as a primary shredder in metal plants, as a wood pre-shredder in many chipboard plants in Germany, Italy, Switzerland, Poland, to name just a few examples.

The HAMMEL RED GIANT has become a brand name that is known and loved for its robust construction and multifunctionality.

There is also the possibility to see a HAMMEL VB 950 DK live, the HAMMEL company invites to its annual demo days at the Bad Salzungen works.