AUMUND offers new conveying and transportation solutions for alternative fuels

04.03.2020Back in July 2019 AUMUND Fördertechnik GmbH began increasing capacity in its engineering team; this signalled the start of new product design in conveying and transportation of alternative fuels. The engineering team has now started the new year with its full complement.

In the early 1990s AUMUND made news by taking over Maschinenfabrik LOUISE in Cologne. In 2006 AUMUND also acquired WTW Engineering in Cologne. Both companies have engineering, patents, production and sales relating to rotary discharge machines and drag chain conveyors. The purchase of these companies and their products gave AUMUND the edge in bringing to market discharge systems such as CENTREX® or LOUISE Rotary Discharge Machines and Rotating Rotary Discharge Machines, and in driving the development of these products. The acquisition of the spare parts business of Maschinenfabrik Besta & Meyer in 2014 rounded off the product portfolio at that time.

As AUMUND continues to pursue this strategic path it is now capable of offering an extended range of products for the alternative fuels sector: The offering includes the AUMUND Trailer Docking Station, the AUMUND Moving Floor, and the AUMUND Rotating Screw Discharger for the conveying and transportation of alternative fuels such as wood chips, wood pellets, RDF, sewage sludge, shredded paper and many more.

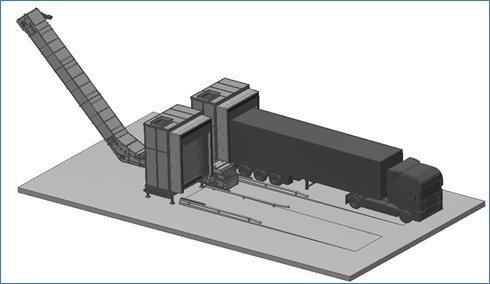

AUMUND Trailer Docking Station

The AUMUND Docking Station is particularly suited to truck unloading with autonomous discharge systems such as walking floors and active or moving bottoms. A separate hydraulic aggregate powers these moving floors so that the unloading of the truck is independent of its traction unit.

AUMUND Docking Station

AUMUND Docking Station

© AUMUND

With the aid of dedusting systems on the Station and a curtain, the discharge effected is largely dust-free. Screw conveyors on the floor of the Docking Station transport the material sideways to an ongoing conveyor. The AUMUND Docking Station impresses with its compact, modular and flexible design. Extensive structural requirements are not necessary. Discharge capacities of 200 m³/h with two Docking Stations have already been achieved.

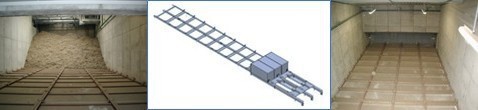

AUMUND Moving Floor

The AUMUND Moving Floor is a reliable unloading system for easy flowing and sticky materials. The Moving Floor consists of a special grating which is individually adapted to the characteristics of the material to be conveyed. The Moving Floor slats are each powered by a hydraulic cylinder, with individual slats retracting below the material in turn, enabling the complete Moving Floor to bring the material forward in the conveying direction.

The Moving Floor can be installed either on a concrete slab or on steel. Classical applications for the Moving Floor are pre- and interim hoppers for wood chips and bark, sawdust, rubber waste, plastic rubbish, sludge, coal-tar mixtures, refuse from the paper industry and many more. Discharge capacities of 40 to 300 m³/h have already been achieved.

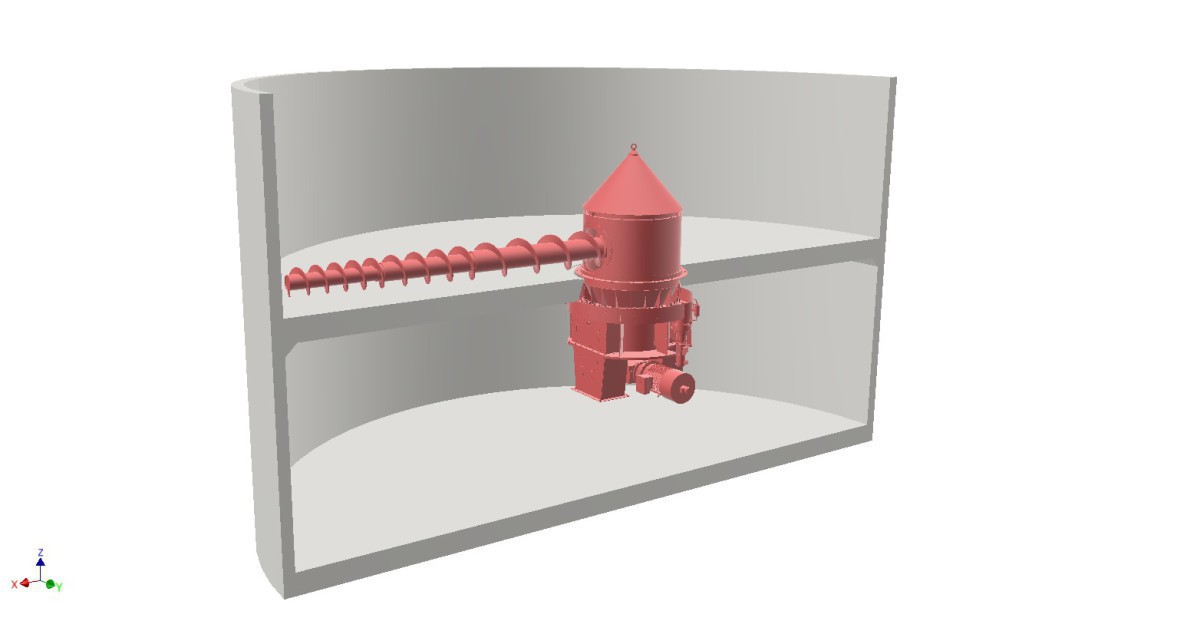

AUMUND Rotating Screw Discharger Type RSD

The Rotating Screw Discharger type RSD is a discharge system for dry or damp bulk materials which do not flow easily. The Screw Discharger travels over the silo floor by rotating around the vertical axis of the cone, and conveys the material into the chute beneath the cone.

AUMUND Rotating Screw Discharger Type RSD in a silo

AUMUND Rotating Screw Discharger Type RSD in a silo

© AUMUND

The Screw Discharger can be adapted to the individual bulk material by variations in the design of features such as the cladding, the teeth, or the pitch of the screw. Screw Dischargers can be installed in steel or concrete silos. Depending on the material properties and the diameter of the silo, conveying capacities of up to 450 m³/h can be achieved. The maximum silo diameter is currently around 25 m.