Better recycling of plastic packaging: new process extracts fragrances

01.06.2023What doesn't smell good is hard to recycle. This simple rule also applies to the growing volume of plastic waste worldwide.

Common HDPE packaging for cleaning agents

Common HDPE packaging for cleaning agents

© Fraunhofer LBF

One way to recycle it in an environmentally compatible and climate-friendly manner as high-quality post-consumer recyclates is through improved sorting and reprocessing. Until now, the reduced material quality has considerably limited the reuse of plastic recyclates, and this is mainly due to their odor. Scientists at the Fraunhofer Institute for Structural Durability and System Reliability LBF have developed a new environmentally friendly process on a laboratory scale to remove odors from plastic packaging. Fraunhofer LBF presented the results of the research project at the Plastics Recycling Show Europe PRSE in Amsterdam and will show the results also at Plastics World Expo Europe in Essen (June 14 to 15, 2023, booth C834).

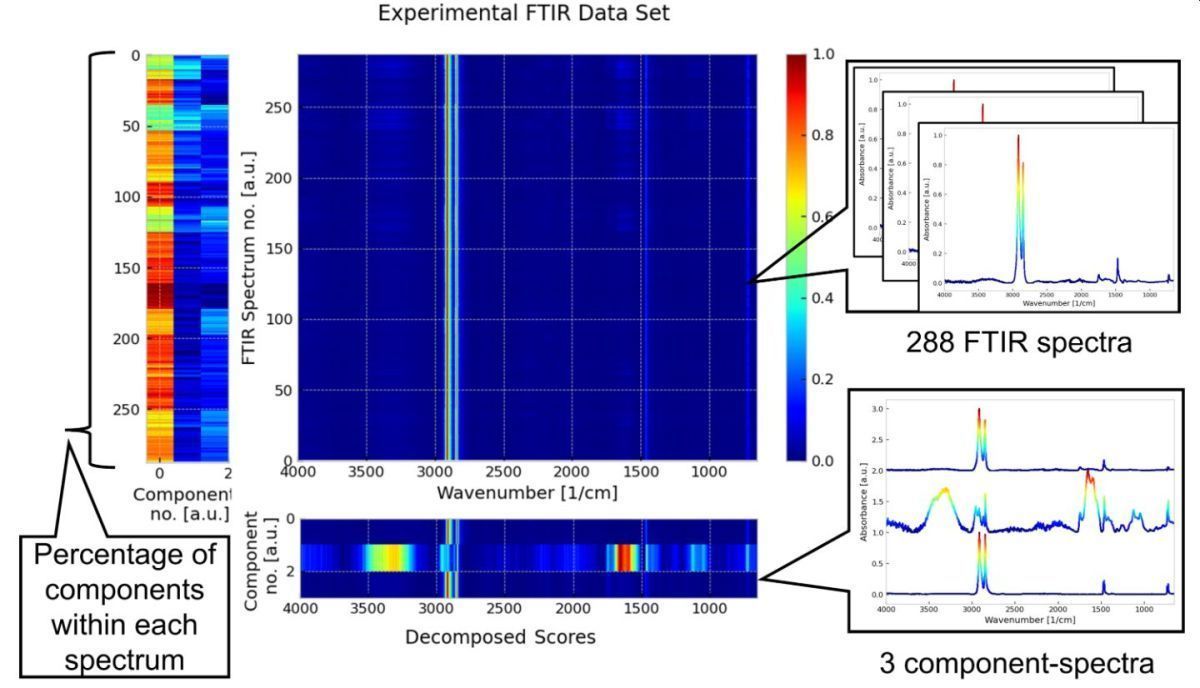

Principle of the multivariate analysis of a set of FTIR spectra. The color scale corresponds both to the intensity and the percentage of HDPE and the extractables (odorants, impurities). The additional substances identified within HDPE are evidently removed by the extraction process. has been identified as the main component of the samples. The extraction pro-cess was optimized based on the analytical data

Principle of the multivariate analysis of a set of FTIR spectra. The color scale corresponds both to the intensity and the percentage of HDPE and the extractables (odorants, impurities). The additional substances identified within HDPE are evidently removed by the extraction process. has been identified as the main component of the samples. The extraction pro-cess was optimized based on the analytical data

© Fraunhofer LBF

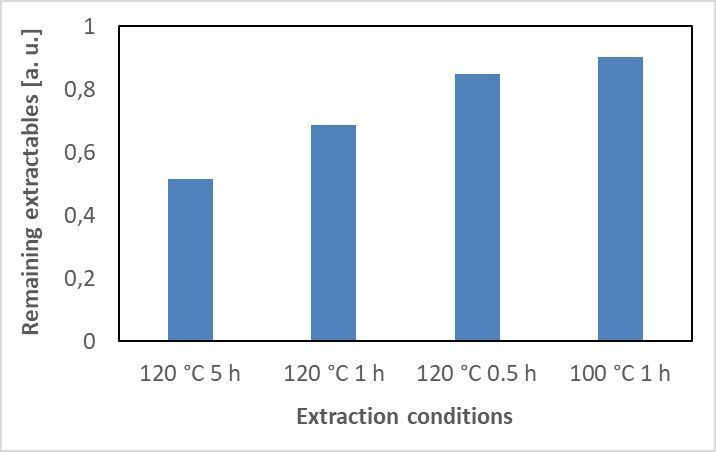

The new process is based on pressurized water extraction. It removes the tracer fragrance limonene from commercial HDPE packaging and does not require organic solvents. This reduces costs and protects the environment. In this way, the material quality of processed plastic waste can be significantly increased within one hour. The in-process analysis is based on infrared spectroscopy and mass spectrometry that provide the research team with data on the chemical composition of the samples as a function of different extraction conditions. The analytical data show that significantly less limonene is present in the samples after extraction. Furthermore, in addition to the fragrance, other impurities and short-chain HDPE are removed from the samples that were originally contained in the packaging. Based on these analyses, the Darmstadt experts determined the optimal process parameters for pressurized water extraction of fragrances from HDPE packaging. "The project results demonstrate the benefits of a systemic approach to solving current plastics technology issues with great social relevance," emphasizes Dr. Guru Geertz, who oversees the project at Fraunhofer LBF.

Impact of the novel extraction process on the content of extractables (odorants, impurities) within commercial HDPE packaging material

Impact of the novel extraction process on the content of extractables (odorants, impurities) within commercial HDPE packaging material

© Fraunhofer LBF

Material analysis with machine learning methods optimizes extraction process

To develop the process, detailed insights into the chemical kinetics of the extraction process were necessary, which were made possible by a novel approach for in-process analytics: Evaluating the data with the aid of machine learning methods was the key to optimize the extraction parameters in terms of the desired economical process control. At the current stage of development, an application scenario for the new process is emerging for the improved treatment of plastic waste: "The extraction process we have developed shows a way to reprocessed single-use plastics with an increased range of applications, and this serves to protect the environment," says Dr. Geertz. Due to the underlying concept, the process is equally suitable for industrialized, emerging, and developing countries, so that all market participants who bring plastic products into the trade can potentially benefit from it.

The project was funded as part of the Fraunhofer-Gesellschaft's internal programs.