Primobius and Mercedes-Benz intend to launch technology partnership for battery recycling

22.03.2022Primobius intends to enter into a cooperation with LICULAR, a wholly-owned subsidiary of Mercedes-Benz AG, aimed at maximising the recycling rate, reducing resource consumption and creating a more circular and sustainable raw materials supply chain. The companies have signed a memorandum of understanding.

Highly pure substances can be fed straight back into the supply chain for battery production

Highly pure substances can be fed straight back into the supply chain for battery production

© Primobius

Primobius shall license the technology for the Mercedes-Benz battery recycling plant to be located at Mercedes-Benz Kuppenheim Operations in Southern Germany. In addition to a technology license to run the recycling plant, the cooperation will then also cover technological support from Primobius. LICULAR recycling activities will commence in 2023 and will provide industrial-scale validation for the integrated Primobius recycling solution.

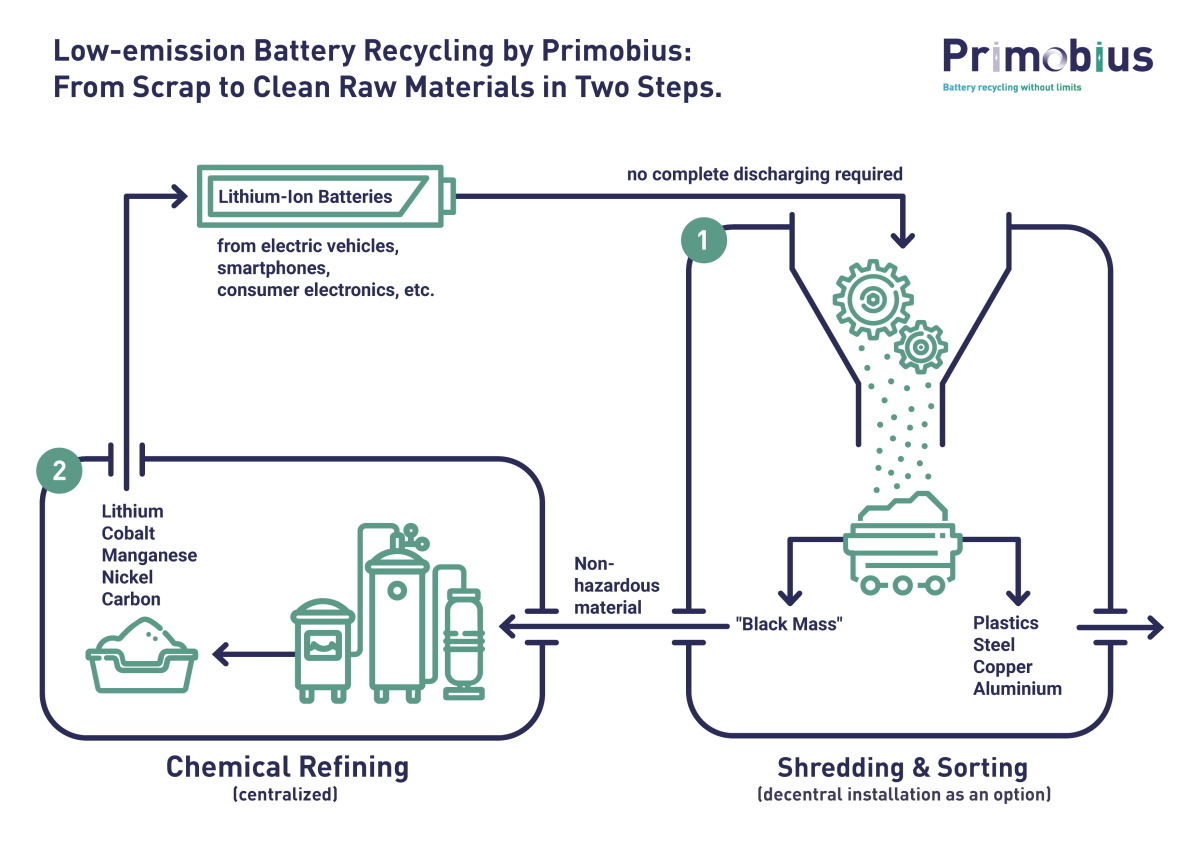

Primobius is a joint venture between Australian company Neometals Ltd. and SMS group. The common goal is to establish an eco-friendly recycling technology for lithium-ion batteries. This is where Primobius relies on a combination of mechanical and hydrometallurgical processes. In a commercial setting the recycling technology targets high energy efficiency and high recovery rates for the metals and valuable materials contained in the batteries.

Low-emission Battery Recycling by Primobius: From scrap to clean raw materials in two steps

Low-emission Battery Recycling by Primobius: From scrap to clean raw materials in two steps

© Primobius

Prof. Hans Ferkel, CTO of SMS group and member of the Primobius Advisory Board: "We are currently seeing a considerable expansion in lithium-ion battery production in Europe. The volume of spent batteries is also set to increase in the coming years. Our partnership with Mercedes-Benz AG shows that with our joint venture Primobius, we have developed the right solution for the market. The materials recovered in our CO2-reduced process include among others lithium, nickel and cobalt. These substances are highly pure and can be fed straight back into the supply chain for battery production."

With a view to the future return of lithium-ion battery systems Mercedes-Benz is expanding its global battery recycling strategy and intends to build its own battery recycling factory in Kuppenheim. To this end, Mercedes-Benz has founded LICULAR GmbH and is cooperating with Primobius as the technology partner. The planned CO2-neutral facility is intended to cover an annual capacity of 2500 tons. The recovered materials will be fed back into the recycling loop.

Jörg Burzer, Member of the Board of Management of Mercedes-Benz Group AG, Production and Supply Chain Management: "Mercedes-Benz is pursuing a clear goal with a view to conserving resources: a maximum circular economy for all raw materials used. Sustainable battery recycling is a key factor in this - worldwide. With our new recycling plant at the Kuppenheim location, together with Primobius we are increasing the recycling rate to more than 96 % while expanding our own expertise in the area of battery value creation. We are taking a decisive step toward closing the recycling loop in e-mobility."

The direct integration of hydrometallurgy into the overall concept of a recycling plant is a core element in the realization of sustainable battery recycling, where the materials obtained can be re-used for the production of new cells. Across Europe, Mercedes-Benz will be the first automotive manufacturer to operate its own recycling plant including hydrometallurgical treatment and aims to be able to achieve recovery rates of over 96 percent (in relation to the battery weight).

As Horst Krenn, Managing Director of Primobius, says: "Intelligent recycling significantly enhances the CO2 balance of lithium-ion batteries and shortens the time to reach the CO2 “break-even” of electric cars in the future. We are proud to be one of the first to realize a resource-efficient recycling technology in the heart of Europe. The joint project with Mercedes-Benz shows that our two-stage recycling process, and particularly the high recovery rates with hydrometallurgy, already meets the industry's needs today."

The project will be overseen with scientific support from the renowned research institutes Karlsruhe Institute of Technology (KIT) and the Technical Universities of Clausthal and Berlin. The project received to prospect of funding by the Federal Ministry for Economic Affairs and Climate Action.