Resource efficiency with an optimized sorting method

06.12.2018The new video on plastics recycling published by the VDI Center for Resource Efficiency (VDI ZRE) shows how packaging waste can be turned into new products. Two recycling companies are introduced along with a manufacturer of detergents and cleaners, who uses recycled plastic material from the Yellow Sack provided by the Duales System Deutschland GmbH (The Green Dot) for his product packaging.

In Germany alone, two and a half million tons of plastic packaging land in the Yellow Bin or Yellow Bag each year. In the fight against plastic waste and following the EU recycling strategy, in Europe any plastic packaging shall be made reusable while, in future, the consumption of non-returnable plastic shall be reduced. How old plastic packaging can be processed into new products is illustrated by the VDI ZRE in its film entitled “Recycling plastics – Resource efficiency with an optimized sorting method”.

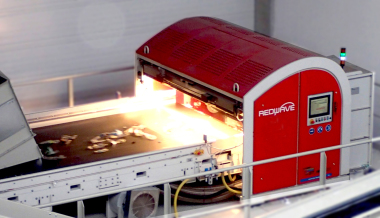

The film depicts how, at first, the different sorts of plastic from the Yellow Bag are sorted – as it is the case at the MEILO GmbH in Hesse. There, the readily processible proportions of plastic HDPE (High-Density Polyethylene), PP (Polypropylene) and PET (Polyethylene terephthalate) are pressed into bales. They are a sought-after secondary raw material in the plastics processing industry: in the so-called downcycling process, for example, new plastic pipes or pallets are created from recycled HDPE. Old bottle caps made of PP are often turned into flower pots or buckets – and what once hast been a PET packaging will be found again in fibers of fleece pullovers or lawn furniture. However, the mixed plastics contained to a large extent in the packaging waste as well as other wastes end up in the waste incineration plant. Thus, a genuine material cycle has not been created.

To make a bottle into another bottle, old packaging material needs further processing. The Systec Plastics GmbH in Thuringia, the second recycling company presented in the film, runs a special plant that shreds, cleanses and sorts the recyclable sorts of plastic HDPE, PP and PET from the plastic waste and processes them into high-quality granules. The film by the VDI ZRE demonstrates the way the Werner und Mertz GmbH, manufacturing laundry detergents and cleaning supplies, uses this recycling material to produce their product packaging: the company’s HDPE bottles and PP lids are made of 100 % recycled plastics from the Yellow Bag. However, the PET granules produced are not sufficient for the production of new containers, which is why it is mixed with recycling material gained from returnable bottles: new, ready-to-use solutions are the result. The example shows: plastics from the Yellow Bag can be maintained in a cycle – and raw materials and energy originally invested into their production are preserved.

With the WebVideomagazin “Resource Germany TV“, the VDI Center for Resource Efficiency (VDI ZRE) presents environmentally aware behaviour in small and medium-sized companies. The series of films shows examples of Good Practice in companies from different industries that may act as a role model for the responsible use of resources. All films and videos are available in the internet at www.ressource-deutschland.tv or on Youtube under “Resource Germany“.