The remanufacturing of used machines is to Herbold Meckesheim like steel to its plants

25.11.2024Herbold Meckesheim has been thinking about the circular economy from the very beginning. When the special machine builder offered its first solutions for plastics recycling some 40 years ago, not everyone understood its mission. Today, a world without plastics recycling is hard to imagine – and certainly not the future. From the very beginning, Herbold Meckesheim's recycling solutions also took into account the life cycle of the machines themselves. They should not only contribute to a functioning circular economy, but also be part of it.

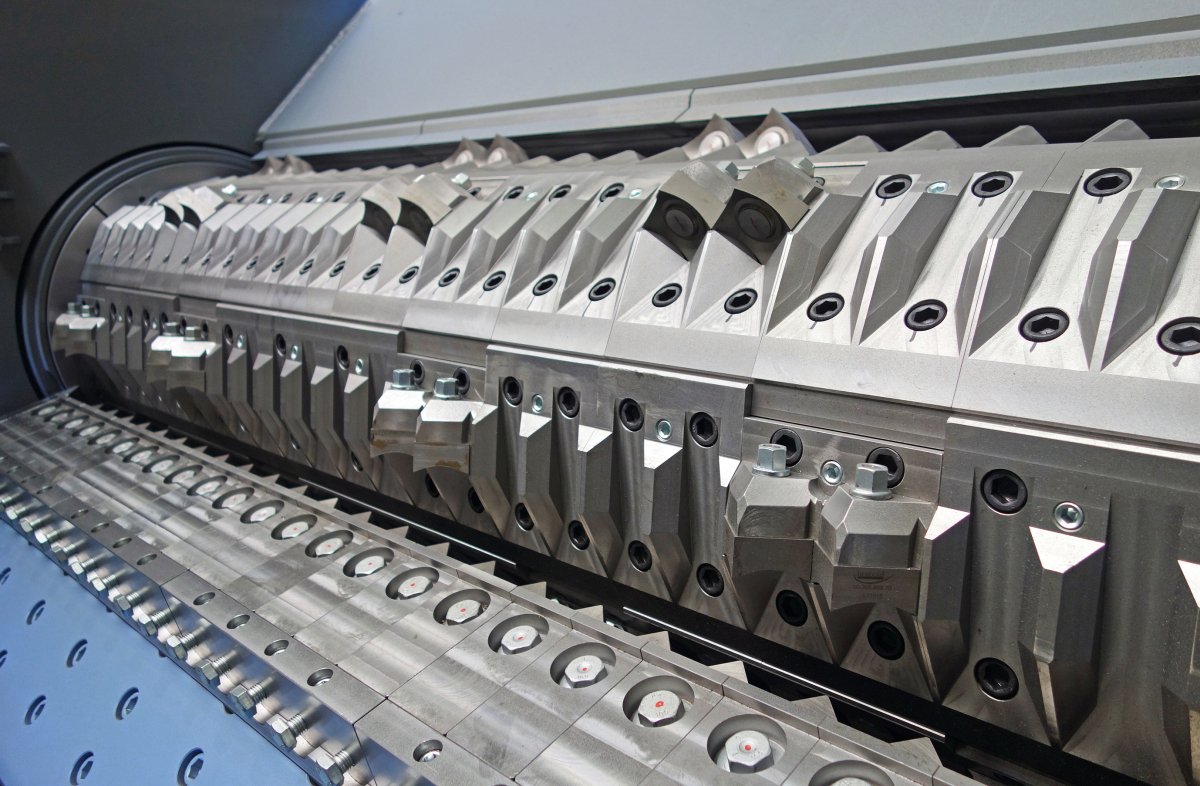

Rotor of a single-shaft shredder 60/210 with bolted-on knife cassettes

Rotor of a single-shaft shredder 60/210 with bolted-on knife cassettes

© Herbold Meckesheim

With increasing scarcity of resources, rising energy costs, and growing environmental awareness, this perspective may become even more important in the upcoming years. Herbold Meckesheim had durability and sustainability in mind when considering its machine design four decades ago. Examples: From the beginning, no machines were made of cast iron because the material could break. The insides of the welded steel housings are covered with replaceable plates to protect the frame. And the diverse rotors used in the various shredders, mills, and granulators are equipped with screwed-on cassettes for the knives. The latter protects the rotor and makes hard facing obsolete.

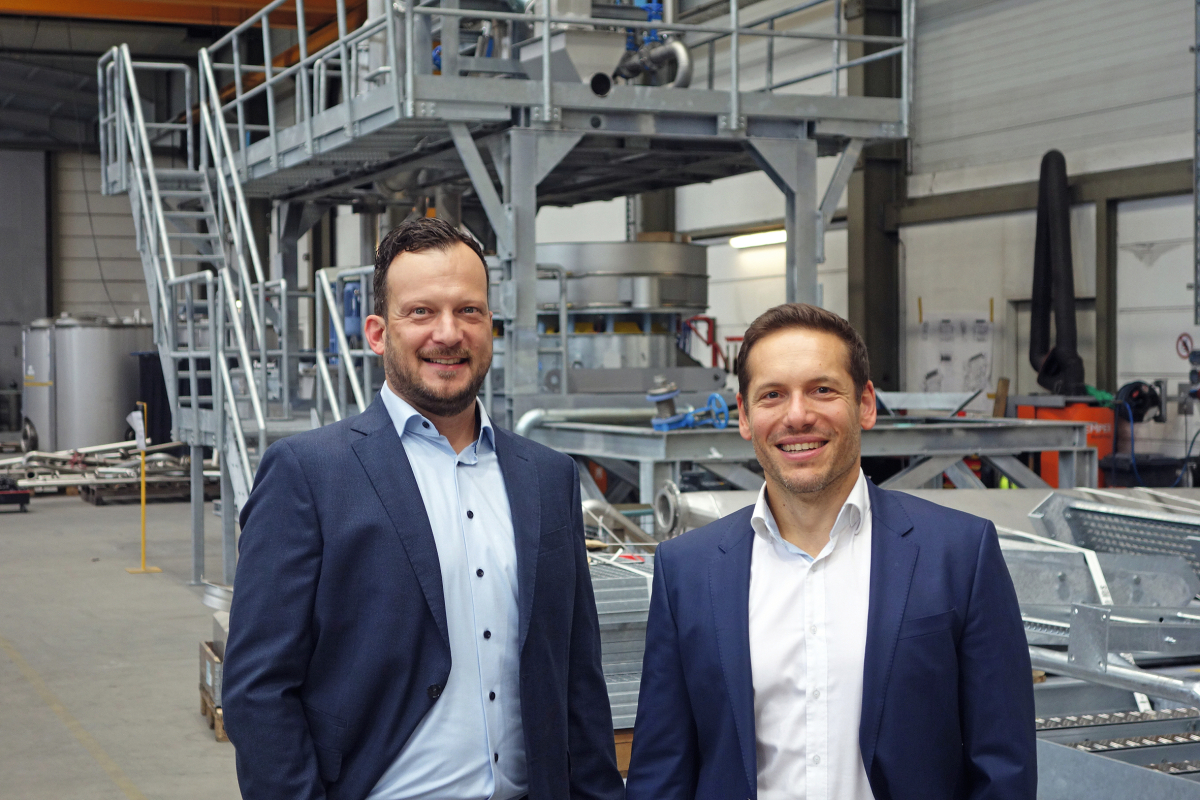

A granulator SMS 80/120 before refurbishment

A granulator SMS 80/120 before refurbishment

© Herbold Meckesheim

The bolted-on cassettes represent two essential aspects of sustainable machine design: a substantial degree of wear protection and ease of maintenance. While Herbold Meckesheim was developing its first machines, the company was already trading in used granulators from other suppliers. The Herbold designers took this as an opportunity to focus on durability and accessibility for easy repair and maintenance. In principle, leaders of the Meckesheim-based company believe it is possible to put a reconditioned machine back into operation with virtually no loss of performance – regardless of the application. Some customers have their machines overhauled every twelve months. In cases when a customer wants a larger model, Herbold Meckesheim provides a buy-back offer for the previous, smaller machine, refurbishes it, and then sells it again.

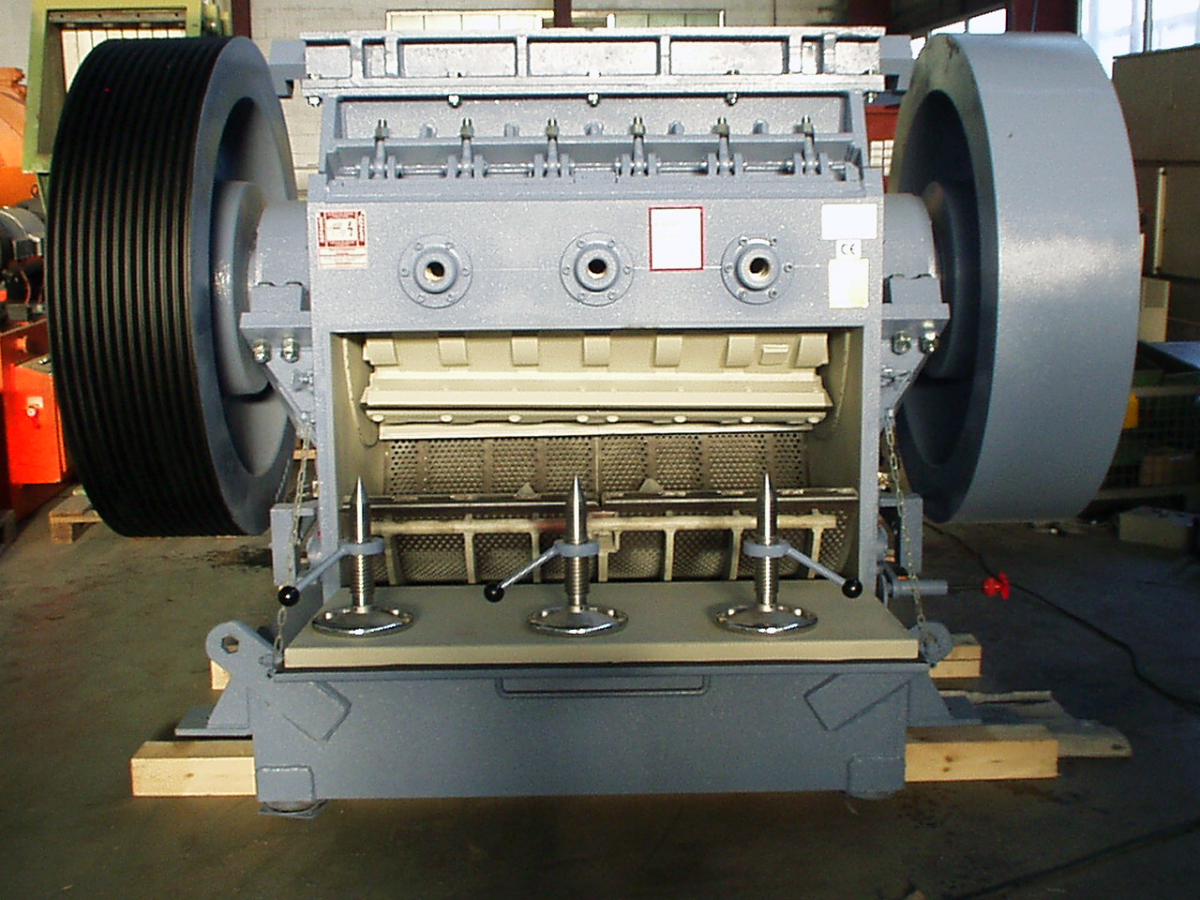

A granulator SMS 80/120 after refurbishment

A granulator SMS 80/120 after refurbishment

© Herbold Meckesheim

Whether it is a small pulverizer or a modular plant solution for washing and recycling lines with several tons of throughput, the principle is the same. The Herbold Meckesheim focus remains on ease of maintenance, wear protection, and a long service life as well as low energy and resource requirements. This approach considers the growing importance – and necessity – of a functioning circular economy, not only with regard to the reprocessing of plastics.

One thing must not be forgotten: Focusing on the restoration of saleable machines is not only a promising concept for the future, it is good business.