Sesotec’s FLAKE SCAN analysis system saves time and money

The quality of plastic flakes and regrind is crucial in determining whether plastic processors and manufacturers can profitably use and sell plastic recyclate.

Depending on how the recyclate will be used, elaborate manual, visual, or thermal sample analyses are often necessary in order to assess the quality of a batch of materials. Sample analyses are also used as a means of evaluating the effectiveness of the recycling sorting process. Such sample analyses are hardly representative, and furthermore require additional resources, costs, and time.

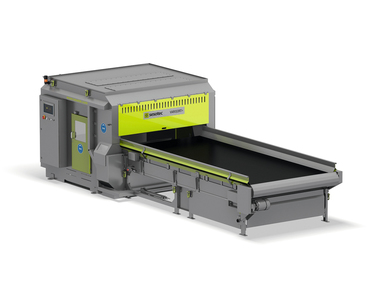

FLAKE SCAN by Sesotec was developed to help reduce the effort involved in various analysis techniques. In just a few minutes, the device can reliably determine the precise quality of plastic flakes and regrind. The FLAKE SCAN analysis system delivers data that can be quickly leveraged to make decisions about whether plastic flakes and regrind are pure enough for profitable use. It can also provide insights into the effectiveness of an entire recycling process and help ensure that individual plant components are functioning as they should.

A combination of up to three sensors (color, near infrared, and metal) automatically provides precise, reproducible analyses of material samples by detecting color errors, plastic types, and metallic contaminants. The composition of each batch of plastic flakes can be determined within minutes. Representative results can be reached with a sample volume as small as 8 l. At its maximum throughput, FLAKE SCAN can analyze up to 20 kg/h. The device also offers easy operation, with an intuitive touchscreen as well as automated reporting and archiving.