STEINERT: optimize sorting and recycling rates using high-tech facilities

In 1991 the German government passed a packaging regulation in order to stem the rising flood of plastics that was swamping the country. The regulation requires manufacturers who put plastic packaging into circulation to fund the dual waste recovery system (Duales System). As a result, waste disposal companies can separate the various recoverables from the plastic waste that is thrown into yellow recycling bins. Some of this waste can be recycled while the rest is incinerated. Since then, the German government has amended the packaging regulation seven times in order to adapt it to current EU legislation and environmental challenges. The eighth amendment will go into force on 1 January 2019 and require the recycling rate for plastic packaging to be increased from today’s 36 % to 63 % in 2022. That’s because the meteoric rise of online commerce has caused the flood of plastic to become too large.

The amendment poses a challenge for the operators of sorting systems, because their facilities will have to sort plastic components on a scale that exceeds the capabilities of the equipment. These components include PE and PP films, which have generally been incinerated until now. In order to cope with this increase, several waste disposal companies have already announced that they will build additional sorting facilities. “STEINERT has magnetic and sensor sorting machines in its portfolio that enable it to supply these companies with pioneering technologies that can meet the higher recycling rates of the new packaging regulation,” says Hendrik Beel, a managing director at the STEINERT Group.

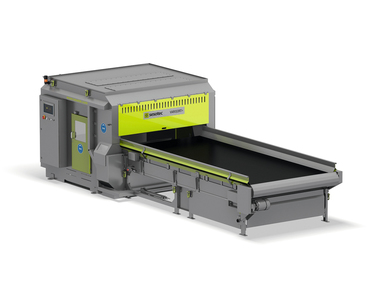

Stay calm: “Calming tunnel” prevents films from flying away during sorting

Films made of PVC or organic materials and agricultural films all share one difficult characteristic: They’re hard to sort by machine. These films are so light that they lift off from the sorting system’s conveyor belt, fly about, and are difficult for camera systems to reliably detect. In an act of desperation, many sorting companies reduce the belt speed far below the standard rate of 2.8 m/s – to the detriment of the throughput rate and the sorting system’s profitability.

STEINERT has come up with a solution for this problem: the sorting machine UniSort Film. It has a “calming tunnel” – otherwise known as an active object control (AOC) system – mounted above the conveyor belt. This tunnel generates a gentle airflow that is just strong enough to push plastic films down onto the belt and keep them in place. It enables waste disposal companies to work with belt speeds of up to 5 m/s and increase the sorting throughput.

But how does the system distinguish between different types of plastic? The answer is the cutting-edge detection unit UniSort PR, which uses a light source to illuminate the conveyor belt while a near-infrared (NIR) camera records the reflected light. STEINERT software analyses the light’s spectrum in order to determine what kind of plastic the system is dealing with. “We use a line-scan camera that simultaneously monitors 320 measurement points across the conveyor belt’s total width,” says Beel. “That is much more than with conventional systems, which use cameras with a focus that jumps around between different points. Our NIR technology enables companies to sort several tons of plastic each hour and do so fully automatically with a success rate of up to 99 %.” This results in cleanly separated products whose quality is so high that they can once again be realistically sold to China.

UniSort Black: Facility operators can sort out black plastics for the first time

Until recently, black plastics generally ended up in the residual fraction for incineration because even NIR cameras cannot reliably detect them. That’s because the soot used to blacken the plastic absorbs electromagnetic radiation in both the visible and the infrared wavelength regions. This makes the machines blind for such materials. However, in view of rising recycling rates, companies urgently need to sort black plastics as well.

In response to this situation, STEINERT has developed UniSort Black, a sorting system that uses hyperspectral imaging (HSI) technology. “Thanks to its extremely high spectral resolution, the camera can also detect black objects that are invisible to conventional NIR systems,” explains Beel. “It enables facility operators to specifically sort out black plastics.” As a result, they not only meet the new packaging regulation’s higher recycling rates. “They can also produce cleanly separated valuable granules that they can sell for recycling purposes. That way, they can quickly recoup their investment in the system.”

Germany’s new Commercial Waste Regulation (GewAbfV) increases the pressure on sorting companies

However, it’s not just the packaging regulation that will become stricter in Germany, as the country’s commercial waste regulation was also tightened on 1 August 2017. In order to ensure that more of the recoverables contained in commercial, construction and demolition waste are recycled, the German government has redefined the technical requirements of sorting facilities. Waste disposal companies now have to retool their facilities by 1 January 2019 so that they can more precisely extract plastics, wood, metals and glass from waste mixtures. The materials then need to be cleanly separated and recycled. The new sorting rate is 85 %, 30 % of which has to be recycled. To enable companies to achieve these targets, STEINERT is offering the NIR sorting system UniSort PR. At the VDMA practical days in the outdoor area of the IFAT trade fair, STEINERT will present a mobile solution for waste wood processing companies, for example, that want to meet the GewAbfV requirements. The system is an all-new mobile separator for iron and non-ferrous metals. It separates iron and non-ferrous metals at an early stage of the process. In addition, the mobile system is flexible and can be used without a construction permit.

“Many companies still aren’t prepared to meet the strict requirements,” says Beel. Another aim is to increase the likelihood of sales on the global market. “China, which used to be one of the biggest purchasers of scrap metal, has drastically decreased its import quotas and is steadily reducing the share of permitted contaminants. As a result, companies that cleanly separate materials gain a competitive edge.”

Cleanly sorting metals – a success factor for metal processing firms

In the area of metal processing, STEINERT is focusing on two factors: purity and the processing of fine fractions. Engineers began using combinations of different sensors to achieve steadily increasing sorting depths well before China decided to reduce its import quota for mixed products. An example of this is the STEINERT KSS multi-sensor machine, which can cleanly separate metals. The machine is a platform on which a variety of sensors are used: 3D, colour and induction recognition systems. The machine can also be equipped with a fourth sensor (near-infrared, X-ray transmission, or X-ray fluorescence sensors). The X-ray sensor enables the system to separate heavy metals from a fraction of lightweight metals such as aluminium. The recognition software developed by STEINERT is future-proof, because the programming experts made sure that new recognition algorithms could be added.

For metals recycling, STEINERT offers the non-ferrous metals separator STEINERT EddyC® FINES so that fine fractions that are extracted from wind sifters, for example, don’t have to be expensively disposed of at landfills. It is a sorting system that enables the splitter plate to be precisely adjusted so that even non-ferrous metals from extremely fine residues (grain sizes of up to 0.5 mm) can be recovered. STEINERT’s UniSort Flake C also operates in the fine-grain range and saves landfill costs by colour sorting the fraction extracted from the non-ferrous metals separator. The UniSort Flake C can detect differences in colour so that it can discharge copper (all shades of red), for example, and subsequently distinguish between different shades of grey, such as those of zinc and lead.

Stricter new RAL guidelines for fertilizer from organic waste

In 2018 companies will also face challenges associated with the production of fertilizers and soil improvers from organic waste. That’s at least the case when they advertise their products with the RAL quality mark for compost (RAL-G2-251) – a voluntary product certification offered by the Bundesgütegemeinschaft Kompost (BGK), which, in turn, is certified by the Deutsches Institut für Gütesicherung und Kennzeichnung (RAL). Until now, this certification required manufacturers to have no more than 25 cm2 of contaminants in each litre of fresh material. On 1 July 2018 this value will drop to 15 cm2. More than ever before, operators of composting facilities will then need high-performance sorting systems that extract contaminants from the increasingly contaminated organic waste. Technologies such as the UniSort sorting system from STEINERT lets manufacturers achieve rates as high as 99 % at a throughput of up to 10 t/h.

Hall B6, 451/550